3046553

Official Distributor

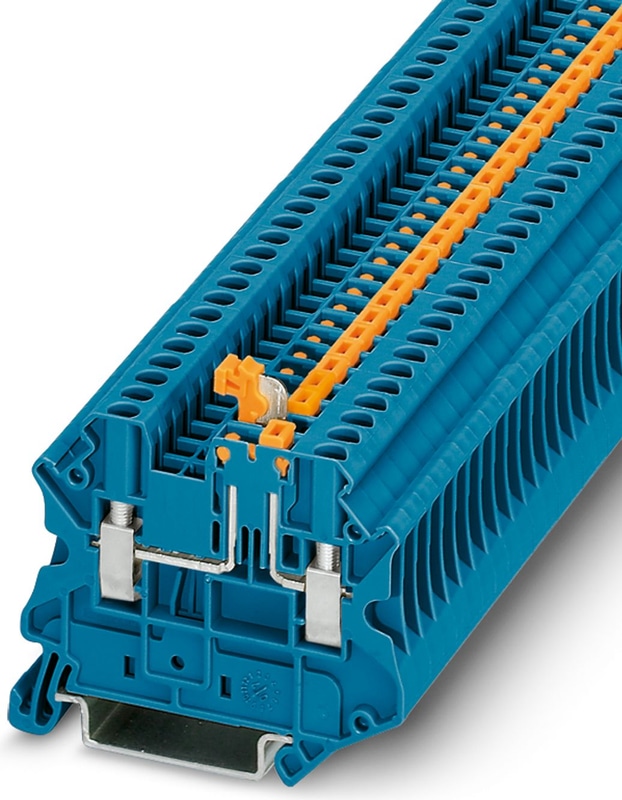

Official DistributorUT 2,5-MT BU - Knife-disconnect terminal block

Knife-disconnect terminal block, nom. voltage: 400 V, nominal current: 20 A, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting: NS 35/7,5, NS 35/15, color: blue

- Compact design and high current carrying capacity of 20 A

- Double bridge shaft enables individual potential distribution and supply

UT

The Phoenix Contact UT Series comprises feed-through terminal blocks that utilize screw connection technology, offering reliable and maintenance-free conductor connections for various industrial applications. These terminal blocks are designed to accommodate a wide range of conductor cross-sections, providing flexibility and ease of installation.

Key Features:

- Screw Connection Technology: The UT Series employs a screw connection method, ensuring secure and durable connections. The Reakdyn principle, a screw locking technique developed by Phoenix Contact, prevents loosening of terminal block screws, eliminating the need for retightening.

- Versatile Conductor Accommodation: These terminal blocks can connect solid and stranded conductors without ferrules, even above the nominal cross-section, due to their large wiring space. This feature allows for universal application across various conductor types and sizes.

- Compact Design: The UT Series offers a compact, space-saving design, making it ideal for smaller control cabinets and boxes where space is at a premium.

Product properties

| Area of application | Railway industry |

| Area of application | Machine building |

| Area of application | Plant engineering |

| Number of Connections | 2 |

| Number of rows | 1 |

Insulation characteristics

| Overvoltage category | III |

| Degree of pollution | 3 |

Electrical properties

| Rated surge voltage | 6 kV |

| Maximum power dissipation for nominal condition | 0.77 W |

Connection data

| Number of connections per level | 2 |

| Nominal cross section | 2.5 mm² |

| Rated cross section AWG | 12 |

Level 1 above 1 below 1

| Screw thread | M3 |

| Tightening torque | 0.5 ... 0.6 Nm |

| Stripping length | 9 mm |

| Internal cylindrical gage | A3 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross section rigid | 0.14 mm² ... 4 mm² |

| Cross section AWG | 26 ... 12 (converted acc. to IEC) |

| Conductor cross section flexible | 0.14 mm² ... 4 mm² |

| Conductor cross section, flexible [AWG] | 26 ... 12 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.14 mm² ... 2.5 mm² |

| Flexible conductor cross section (ferrule with plastic sleeve) | 0.14 mm² ... 2.5 mm² |

| 2 conductors with same cross section, solid | 0.14 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible | 0.14 mm² ... 1.5 mm² |

| 2 conductors with same cross section, flexible, with ferrule without plastic sleeve | 0.14 mm² ... 1.5 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Nominal Current | 20 A (with 4 mm² conductor cross section) |

| Maximum Load Current | 20 A (with 4 mm² conductor cross section) |

| Nominal Voltage | 400 V |

| Nominal cross section | 2.5 mm² |

Dimensions

| Width | 5.2 mm |

| End cover width | 2.2 mm |

| Height | 57.8 mm |

| Depth on NS 35/7,5 | 49.1 mm |

| Depth on NS 35/15 | 56.6 mm |

Material specifications

| Color | blue |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

Surge voltage test

| Test voltage setpoint | 7.3 kV |

| Result | Test passed |

Temperature-rise test

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Result | Test passed |

Power-frequency withstand voltage

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

Mechanical data

| Open side panel | Yes |

Mechanical strength

| Result | Test passed |

Attachment on the carrier

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 1 N |

| Result | Test passed |

Test for conductor damage and slackening

| Rotation speed | 10 (+/- 2) rpm |

| Revolutions | 135 |

| Conductor cross section/weight | 0.14 mm² / 0.2 kg |

| Conductor cross section/weight | 2.5 mm² / 0.7 kg |

| Conductor cross section/weight | 4 mm² / 0.9 kg |

| Result | Test passed |

Needle-flame test

| Time of exposure | 30 s |

| Result | Test passed |

Oscillation/broadband noise

| Specification | DIN EN 50155 (VDE 0115-200):2018-05 |

| Spectrum | Service life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

Shocks

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Semi-sinusoidal |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

Ambient conditions

| Ambient Temperature (Operation) | -60 °C ... 110 °C (Operating temperature range incl. self-heating; for max. short-term operating temperature, see RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

Standards and Regulations

| Connection in acc. with standard | IEC 60947-7-1 |

Mounting

| Mounting Type | NS 35/7,5 |

| Mounting Type | NS 35/15 |

Why Proax for Phoenix Contact 3046553?

Proax is an authorized distributor of Phoenix Contact 3046553 and one of Phoenix Contact's largest distributors in North America. Our highly skilled in-house technical team is ready to assist with any technical needs.

Have a question in mind? to help you get the right product as quickly as possible for your project. We're always here to help!

| Pack Size | 50 |

UT 2,5-MT-P/P - Knife-disconnect terminal block, With test socket screws for insertion of test plugs, nom. voltage: 400 V, nominal current: 20 A, number of connections: 2, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

UT 2,5-MT-P/P - Knife-disconnect terminal block, With test socket screws for insertion of test plugs, nom. voltage: 400 V, nominal current: 20 A, number of connections: 2, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray UT 2,5-MTD P/P - Feed-through terminal block, With test socket screws for insertion of test plugs, nom. voltage: 630 V, nominal current: 24 A, number of connections: 2, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

UT 2,5-MTD P/P - Feed-through terminal block, With test socket screws for insertion of test plugs, nom. voltage: 630 V, nominal current: 24 A, number of connections: 2, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray UT 2,5-MTD P/P BU - Feed-through terminal block, With test socket screws for insertion of test plugs, nom. voltage: 630 V, nominal current: 24 A, number of connections: 2, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: blue

UT 2,5-MTD P/P BU - Feed-through terminal block, With test socket screws for insertion of test plugs, nom. voltage: 630 V, nominal current: 24 A, number of connections: 2, connection method: Screw connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: blue