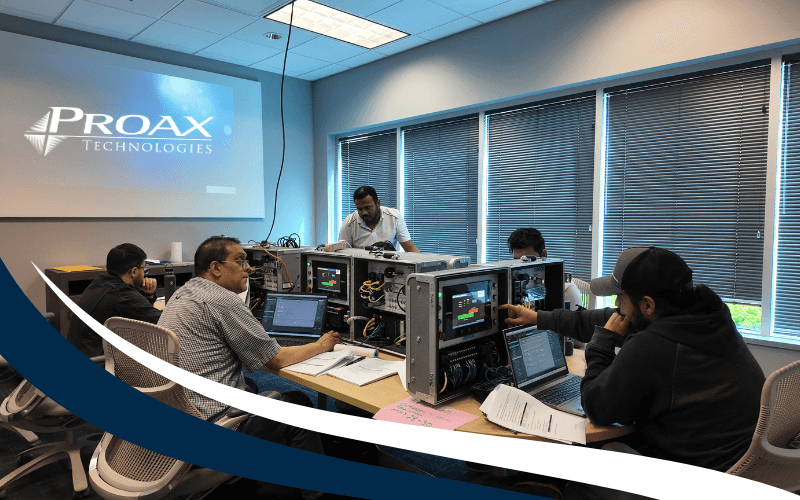

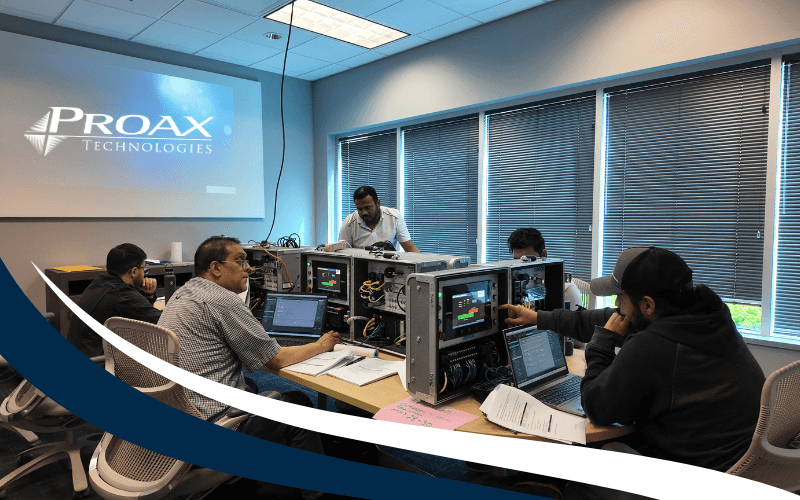

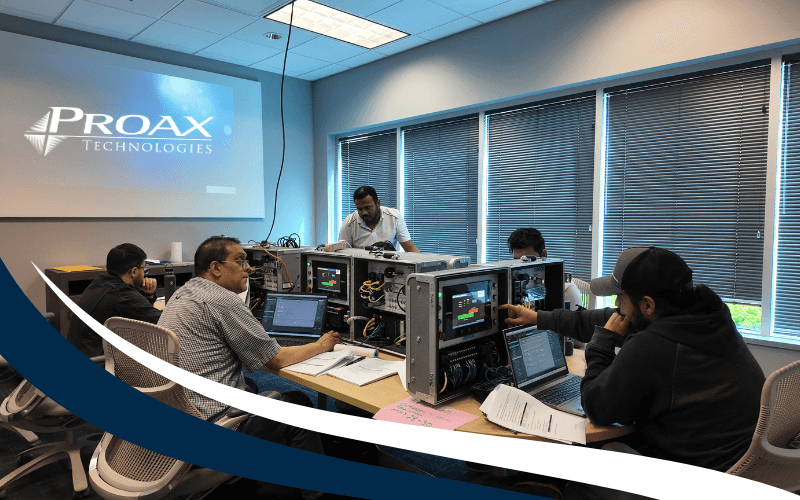

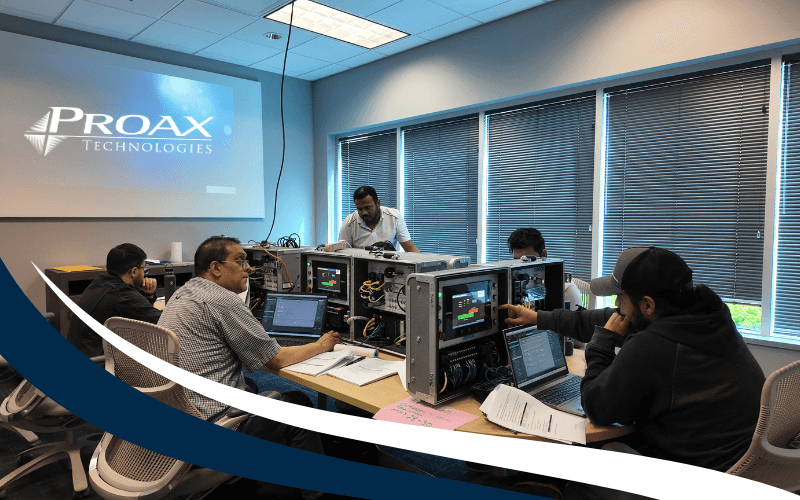

Get Trained by Industry Experts

With the help of our technical experts and our partners, we build and customize trainings to your needs. We offer on-site training to your employees or host private training events at our local offices.

Sysmac: Maintenance

This training aims to demonstrate the various debugging features available in Sysmac Studio, Omron's programming software. You will learn to create and export a project, followed by an overview of the software, covering configuration and programming elements, and finally focusing on debugging tools such as going online with the controller, modifying and viewing online variables, and data tracing.

Hands-on training

- Duration 7 hours

- Lunch provided

- Exercise and test on didactic equipment: PLC, HMI, EIP and ECat I/O coupler with different input/output cards

- Pricing will be discussed after filling out the form.

Customer or Proax Site

Workshop

Sysmac: Configuration and Programming

This training aims to introduce Omron's Sysmac Studio platform and to understand how to configure a PLC and an HMI according to various aspects: EtherCAT and Ethernet IP communications, inputs/outputs, and variable types. Subsequently, a second section of the training is devoted to programming concepts such as the types of languages used and the types of data. Finally, it concludes with the different debugging tools available in Sysmac Studio.

Customer or Proax Site

Workshop

Motion Control: Motor Sizing

The objective of this training is to bridge the theoretical concepts of mechanics applied in the context of automation with the selection of an Omron servo motor. We will present the software as well as some mechanical calculations. Then, we will discuss the motion profile and subsequently provide a concrete calculation example. Finally, we will import the .MST file into Sysmac Studio.

Customer or Proax Site

Workshop

Motion Control: Axis Start-Up

During this training, you will learn about the differences between the types of axes offered in Omron controllers. You will also cover configuring safety parameters and tuning the servo motor and application. Finally, the last section of this training is dedicated to various function blocks (Power, Stop, Homing, Move, etc.) for executing axis control.

Customer or Proax Site

Workshop

Machine Safety

During this training, you will explore the various uses of Omron safety products based on the communication protocol used. Subsequently, you will learn about configuring each component and manually programming the safety network. Finally, concepts of automatic programming and simulation of the programming will be introduced.

Customer or Proax Site

Webinar

Motion Control: Advanced

This training covers various aspects of advanced axis control in Omron PLCs. You will learn about real and virtual axes, as well as axis groups. The training will also cover different types of synchronization such as gearing and camming, and the possibility of phase shifting between two axes. Finally, we will conclude with coordinated motion and torque control.

Customer or Proax Site

Workshop

Variable Frequency Drives: Start-Up

This training on variable speed drives includes an overview of the ABB Drives portfolio and a technical review of the ACS580. You will learn how to select a drive, followed by starting a motor coupled with an ABB variable speed drive and configuring various communication modes. Finally, the training covers configuring the "Safe Torque Off" safety functionality, whether wired or via communication.

Customer or Proax Site

Workshop

Industrial Vision: System Design

During this training, you will explore the various industrial applications of machine vision and their practical uses. You will study the different components that make up a vision system, starting from the lens to the controller, covering both theoretical and practical aspects. Finally, an overview of programming will enable you to process images and extract necessary data for your application.

Customer or Proax Site

Workshop

Robot Safety Skill Builder - In Person

This comprehensive course introduces students to essential safety concepts around industrial robots in manufacturing environments. Beginning with standards and regulations for robot safety, the course thoroughly examines risk assessment methodologies and reduction strategies for robot work cells.

The curriculum follows a structured approach with the following components:

**Robot Safety Introduction** – establishing foundational knowledge and regulations

**Traditional Industrial Robots** – exploring specific safety considerations

**Robot Risk Assessment Process** – developing practical skills for hazard identification

**Collaborative Robots** – understanding unique safety challenges

**Collaborative Robot Risk Assessment** – learning specialized techniques

This hands-on, in-person training is ideal for safety professionals, engineers, and technicians who need to reduce risks in facilities using industrial or collaborative robots. Prerequisites include completion of the Safety Skill Builder course.

Customer or Proax Site

Workshop

ACE Version 4 Programming Level 1 - In Person

This 5-day training course will help prepare the attendee to use the ACE Version 4 programming interface. The student will create, store, and test programs. The course covers the integration of the digital I/O robot and Manual Control Pendant subsystems. Attendees will be introduced to the hardware and software architecture and will gain expertise through a comprehensive series of workshops covering basic concepts as well as complex applications.

The curriculum follows a structured approach with the following components:

Introduction – foundational concepts and overview

Hardware and Connections – understanding physical setup

Getting Started with a Robot – initial programming steps

ACE Version 4 – exploring the programming platform

V+ Variables – learning data management methods

Programming Basics – developing core coding skills

Basic Movement – controlling robot motion

Tooling – implementing end-of-arm solutions

V+ Programming – advanced programming techniques

Digital Signals – input/output implementation

Advanced Motion – complex movement patterns

Publishing – finalizing and deploying applications

This hands-on training is intended for engineers, programmers and technicians who will be writing application programs and maintaining existing application programs. There are no prerequisites for this course.

Customer or Proax Site

Workshop

Safety Skill Builder - In Person

In this 2-day course, students will learn the requirements, methods and practical application of machine and process safeguarding. Students will be introduced to applicable regulatory requirements to help them identify and assess machine safety risks, deploy safeguarding concepts based on identified risks and participate in a basic machine guarding inspection process.

The curriculum covers essential safety concepts including:

A practical approach to risk assessment & risk reduction utilizing quantifying techniques

Identify machine and process hazards following general safe guarding regulations

Identify safeguarding requirements using applicable safeguarding regulations and standards

Safety circuit categories / control reliability reviewed and applied in safeguarding class discussions

Hierarchy of control / safeguarding methods applied based on risk discussions

Muting vs. bypassing of safeguarding solutions

Requirements for barrier guards following OSHA and ANSI or other applicable standards from country origins

Stop time measurements and safety distance formulas discussed

Brief overview of Machine Europa

General requirements of machine tools

Complementary controls discussed including Enabling switch and two hand control devices

Workshop (Team assessment on shop floor)

This course is intended for anyone that has responsibilities to reduce machine and process risks in a facility, including both plant employees and corporate employees. Optional 1 day (8 hours) is available.

Customer or Proax Site

Workshop

Mobile Robot Programming and Fleet Management - In Person

This 4-day training course develops a firm foundation of skills and knowledge to get Omron mobile robots configured and moving. From the anatomy of an Omron mobile robot to software configuration and execution of tasks attendees will gain the knowledge and confidence to commission and maintain an Omron mobile robot. Once the robots are understood the course moves into working with multiple robots operating as a fleet.

Topics include:

Mobile Robot Initial Setup

Mobile Runner Software

Mobile Robot Theory

Advanced Map Objects

Routes and Tasks

Digital I/O

Robot Configuration

ARCL

Debug Info

Enterprise Manager

Jobs

Traffic Management

Fleet Pattern Management

Traffic Management Objects

Multi-Robot Avoidance

Advanced Standby Options

This course is intended for Engineers, programmers, and maintenance personnel who will be implementing or maintaining Omron Mobile Robots separately or in a fleet. There are no prerequisites for this course.

Customer or Proax Site

Workshop

CX-Programmer Level 2 - In Person

This 2-day PLC training course provides a further understanding of Omron CP Series, CJ Series, CS Series PLCs and their advanced programming capabilities. Control strategies and programming will be reviewed. Data movement and manipulation, data organization, data collection, data transmission, function blocks, and structured text programming (ST Language) using CX-Programmer will also be covered. Computers are provided to assure hands-on experience programming, downloading, and monitoring data with the PLC.

The curriculum includes:

Review Omron PLC fundamentals

Data movement and manipulation

Organization of data

Ethernet communications/sharing data

Function Blocks

Structured text programming

Formerly known as Intermediate PLC Programming, this course is intended for electricians, technicians, maintenance personnel, control engineers, and individuals who need to be able to understand advanced capabilities of Omron PLCs.

Prerequisites: Before attending this course, attendees MUST have completed the TRN-CX1-PLC-L1-CE: CX-Programmer Level 1 – Programmable Logic Controllers course.

Customer or Proax Site

Workshop

Sysmac NA Series HMI - In Person

This 2-day course will teach the configuration and programming of the **NA Series operator interface terminals** using Sysmac Studio's integrated environment. The course is designed for engineers and programmers who will be using the NA Series operator interface terminals to visualize and interact with their automated equipment.

## Curriculum

The course covers the following topics:

- **Product Introduction**

- **Controller Connections**

- **Project Basics**

- **Pages**

- **Creating an HMI Page**

- **Animations**

- **Online Operations**

- **Basic Screen Objects**

- **Intelligent Application Gadgets**

- **Alarms**

## Target Audience

This course is designed for engineers and programmers who will be using the NA Series operator interface terminals to visualize and interact with their automated equipment.

## Prerequisites

Before attending this course, attendees **MUST** have completed the following course:

**TRN-SYS-PLC-L1-O-CE — Sysmac Programming**

---

*Course Duration: 2 days*

Customer or Proax Site

Workshop

Sysmac Programming - In-Person

This 3-day course will teach the configuration and programming of the controller using Sysmac Studio's integrated environment. Students will be introduced to the architecture of the NJ Series and NX Series Machine Automation Controllers and EtherCAT network.

## Curriculum

The course covers the following topics:

- **Hardware Configuration**

- **IEC Concepts**

- **Sysmac Studio Basics**

- **Ladder Logic**

- **Online Operations**

- **Programming**

- **Software Tools**

- **Troubleshooting and Diagnostics**

- **Advanced Variables**

- **Structured Text**

## Target Audience

This course is intended for engineers and programmers who will be using the NJ Series or NX Series Machine Automation Controllers in their automated equipment.

## Prerequisites

No prerequisites are required for this course.

---

*Course Duration: 3 days*

Customer or Proax Site

Workshop

TMflow Programming - In-Person

This course will introduce the Omron TM Collaborative Robots, their programming software TMflow, and focuses on programming and troubleshooting of collaborative robot applications.

The curriculum includes:

Product Introduction

Safety

TMflow Software

Basics of Robot Motion

Advanced Programming

Robot I/O

Vision Configuration

Vision Applications

Gripper Operations

Additional Motion Functions

Communications

This course is intended for programmers and engineers who will be designing and commissioning applications using the Omron TM Collaborative Robots. Before attending this course, the following eLearning module should be completed via the Omron website: LRN1001 - Introduction to Robotics.

Customer or Proax Site

Workshop

FH/FZ Vision System Programming - In Person

FH/FZ Vision System Programming - In Person

Slug: fh-fz-vision-system-programming

Description: The Omron FH-series vision system is the industry's fastest compact vision system for inspection and position control. Under the same software platform, we also have the FZ-series, and the FH/FZ smart camera. This 3-day course will introduce the major processing items available from image input, measurements, compensate image, support measurement to output results.

The curriculum includes:

Vision System Hardware and Connections

Controller Configurations and Setup

Software Overview / Scenes and System

Vision Applications

Operation Panel (GUI Control for Operators)

Simulation and Remote Operation Software

Basics of calibration and layout modification

Processing Items:

Image Acquisition

Measurements

Compensate Image

Support Measurement

Output Results

Attendees will use the FZ-PanDA software on the FH controller and FH simulator on a PC to program vision applications. The class contains hands-on activities for different applications. This course is intended for electricians, technicians, engineers, maintenance personnel, control engineers and individuals who need to understand the concept of the latest vision technology using Omron Vision Systems.

Prerequisites: Familiarity with Industrial Automation processes, basic computer skills, and Microsoft Windows environment.

Customer or Proax Site

Workshop

Sysmac Motion - In-Person

This 2-day course will teach the configuration and programming of the built-in motion control capabilities of the **NJ Series** and **NX Series Machine Automation Controller** using Sysmac Studio's integrated environment. Students will be introduced to the motion control configuration and commands, as well as connection of servos to the EtherCAT network.

## Curriculum

The course covers the following topics:

- **Introduction to Sysmac Series Motion**

- **System Configuration**

- **Programming Basics**

- **Homing**

- **Single Axis Movement**

- **Synchronized Motion**

## Target Audience

This course is intended for engineers and programmers who will be using the NJ Series or NX Series Machine Automation Controllers for motion control functions in their automated equipment.

## Prerequisites

Before attending this course, the following instructor-led training class **MUST** be attended:

**TRN-SYS-PLC-L1-O-CE Sysmac Programming**

*Course Duration: 2 days*

Customer or Proax Site

Workshop

LVS-95XX Software Training - In-Person

During this course, an overview of the LVS-95XX software is provided, including software setup for specific application standard, calibration of the LVS-95XX system and other system settings such as calibration, creating/deletion of an operator etc. A general understanding of barcode grading parameters, defects in barcodes and some remedial actions for correction is discussed. The various reports the software provides are also covered.

The curriculum includes:

Software installation and connection to verifier hardware

System configuration and calibration

Grading of 1D and 2D symbols and explanations of grading parameters

Explanation of barcode defect analysis

Export and data exchange for reports or other PC applications

Explanation of direct part marking (DPM) verification and grading

Discussion, questions and answers

This training is intended for new users of the LVS-95XX series products. Customer should already have purchased the LVS-95XX series product. Basic computer skills are required; Microsoft Windows knowledge is helpful.

Customer or Proax Site

Workshop

CX-Programmer Level 1 - In Person

This is a 3-day course that combines the Fundamentals of Omron PLCs & Getting Started with Omron CP Series, CJ Series, and CS Series PLCs. The first day provides an introduction to the components of a PLC, basic terminology, memory structure, and I/O programming is defined. PLC addressing is discussed, as well as numbering systems including binary, BCD, hexadecimal, and decimal.

The course objectives include:

Read and convert binary, decimal, hexadecimal, and BCD number formats

Diagram a basic PLC system including hardware, CPU, inputs, outputs, and power supply

Determine the proper address of inputs and outputs in an Omron PLC

Use the CX-Programmer software to communicate to the CJ Series PLC and download/upload programs and I/O tables

Create simple ladder diagrams necessary for utilizing software

Construct, test and run PLC programs

Monitor PLC status online

Save and copy programs

Computers are provided to ensure hands-on experience for PLC programming, monitoring, and troubleshooting. This course is intended for electricians, technicians, maintenance personnel, control engineers and individuals who need to understand the basics of PLC operation and basic interpretation of Ladder Diagrams to identify both inputs and outputs.

Prerequisites: Basic computer skills are required. Windows 98, 2000, XP knowledge is helpful.

Customer or Proax Site

Workshop