3061826

Official Distributor

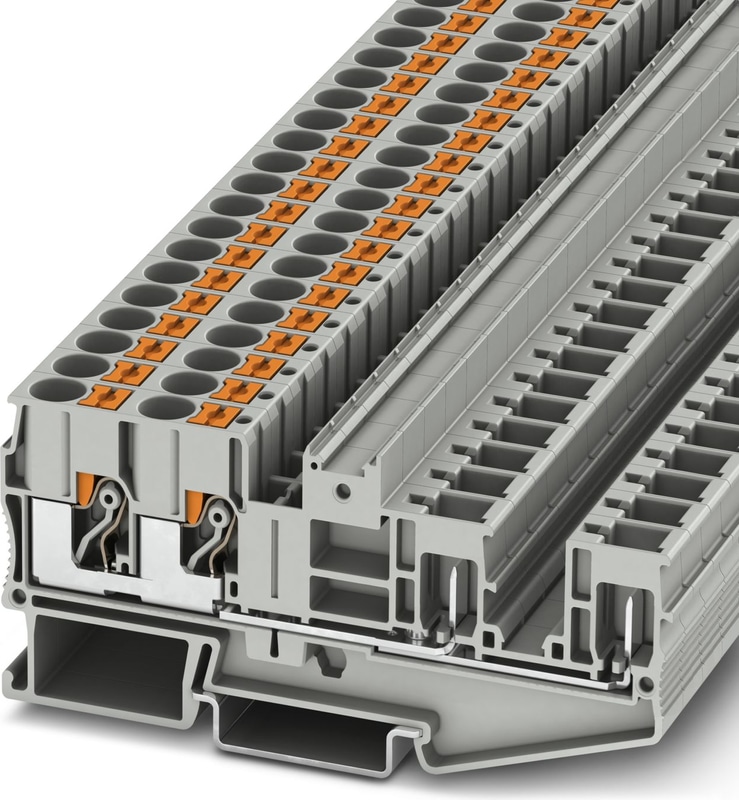

Official DistributorPT 6-QUATTRO/2P - Feed-through terminal block

Feed-through terminal block, nom. voltage: 1000 V, nominal current: 41 A, number of connections: 4, connection method: Push-in / plug connection, Rated cross section: 6 mm2, cross section: 0.5 mm2 - 10 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

- In addition to the testing option in the double function shaft, all terminal blocks provide an additional test pick-off

- The compact design and front connection enable wiring in a confined space

- The Push-in connection terminal blocks are characterized by the system features of the CLIPLINE complete system and by easy and tool-free wiring of conductors with ferrules or solid conductors

- Tested for railway applications

PT

The Phoenix Contact PT Series comprises feed-through terminal blocks that utilize Push-in connection technology, offering efficient and reliable wiring solutions for various industrial applications. These terminal blocks are designed for straightforward conductor insertion, enhancing installation speed and ensuring secure connections.

- Push-in Connection Technology: The PT Series employs a direct plug-in method, allowing solid conductors or conductors with ferrules to be inserted easily without the need for tools. This design facilitates quick and reliable wiring.

- Compact Design: The terminal blocks feature a space-saving form factor, making them suitable for applications where installation space is limited.

- High Electrical Ratings: Depending on the specific model, the PT Series terminal blocks can handle nominal voltages up to 800 V and nominal currents up to 32 A, accommodating a wide range of electrical requirements.

- Versatile Conductor Compatibility: These terminal blocks support various conductor types and sizes, providing flexibility in wiring configurations.

- Integration with CLIPLINE Complete System: The PT Series is compatible with Phoenix Contact's CLIPLINE complete system, allowing for standardized bridging, marking, and testing accessories, which simplifies inventory management and enhances system modularity.

Notes

| General | The max. load current must not be exceeded by the total current of all connected conductors.Current and voltage are determined by the plug used. |

Product properties

| Product family | PT |

| Area of application | Railway industry |

| Area of application | Machine building |

| Area of application | Plant engineering |

| Number of Connections | 4 |

| Number of rows | 1 |

| Potentials | 1 |

Insulation characteristics

| Overvoltage category | III |

| Degree of pollution | 3 |

Electrical properties

| Rated surge voltage | 8 kV |

| Maximum power dissipation for nominal condition | 1.31 W |

Connection data

| Number of connections per level | 4 |

| Nominal cross section | 6 mm² |

| Stripping length | 12 mm |

| Internal cylindrical gage | A5 |

| Connection in acc. with standard | IEC 61984 |

| Conductor cross section rigid | 0.5 mm² ... 10 mm² |

| Cross section AWG | 20 ... 8 (converted acc. to IEC) |

| Conductor cross section flexible | 0.5 mm² ... 10 mm² |

| Conductor cross section, flexible [AWG] | 20 ... 8 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.5 mm² ... 6 mm² |

| Flexible conductor cross section (ferrule with plastic sleeve) | 0.5 mm² ... 6 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 2.5 mm² When using TWIN ferrules, we recommend a minimum ferrule length of 13 mm. |

| Nominal Current | 41 A (observe derating) |

| Maximum Load Current | 41 A (with 10 mm² conductor cross section, rigid) |

| Nominal Voltage | 1000 V |

| Nominal cross section | 6 mm² |

Connection cross sections directly pluggable

| Conductor cross section rigid | 1 mm² ... 10 mm² |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 1 mm² ... 6 mm² |

| Flexible conductor cross section (ferrule with plastic sleeve) | 1 mm² ... 6 mm² |

Dimensions

| Width | 8.2 mm |

| End cover width | 2.2 mm |

| Height | 99.8 mm |

| Depth on NS 35/7,5 | 43.5 mm |

| Depth on NS 35/15 | 51 mm |

Material specifications

| Color | gray |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

Surge voltage test

| Test voltage setpoint | 9.8 kV |

| Result | Test passed |

| Short-time withstand current 6 mm² | 0.72 kA |

| Result | Test passed |

Power-frequency withstand voltage

| Test voltage setpoint | 4.26 kV |

| Result | Test passed |

Mechanical data

| Open side panel | Yes |

Attachment on the carrier

| DIN rail/fixing support | NS 35 |

| Test force setpoint | 5 N |

| Result | Test passed |

Needle-flame test

| Time of exposure | 30 s |

| Result | Test passed |

Oscillation/broadband noise

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Spectrum | Service life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 1.857 (m/s²)²/Hz |

| Acceleration | 0.8g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

Shocks

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

Ambient conditions

| Ambient Temperature (Operation) | -60 °C (max. operating temperature see derating curve) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, no longer than 24 h, -60°C to +70°C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (operation) | 20 % ... 90 % |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

Standards and Regulations

| Connection in acc. with standard | IEC 61984 |

Mounting

| Mounting Type | NS 35/7,5 |

| Mounting Type | NS 35/15 |

Why Proax for Phoenix Contact 3061826?

Proax is an authorized distributor of Phoenix Contact 3061826 and one of Phoenix Contact's largest distributors in North America. Our highly skilled in-house technical team is ready to assist with any technical needs.

Have a question in mind? to help you get the right product as quickly as possible for your project. We're always here to help!

| Pack Size | 50 |