Exploring essential safety measures to protect workers from injuries and accidents when operating machinery is crucial for any workplace. Machine safeguards are vital for ensuring workplace safety. They are designed to prevent contact with hazardous parts, protect from flying debris, and control machine operations. Let's break down the key elements.

In Canada, the CSA standards give specific guidance to hazards in the workplace and the use of machine guarding to protect employees. Choosing the right guarding for your application is the first step. Designing a layout to mitigate access to the hazard based on CSA safe distance to hazard calculations is the next step. Finally, every fence needs an access point for entry, and as such a decision needs to be made as to whom and when access should and can be granted. Choosing the right lock, safety switch, or mechanical interlock can take your simple machine guarding to the highest level of protection.

First, let's talk about fixed guards. Fixed guards are permanent parts of the machine, providing a barrier between workers and moving parts. They are reliable and require minimal maintenance.

Next, we have adjustable guards. These guards can be adjusted to accommodate different operations and materials, offering flexibility while ensuring safety. Adjustable guards are ideal for machines that handle various tasks.

Interlocking guards are another crucial type. These guards are designed to shut off or disengage power when opened or removed, ensuring that the machine cannot operate unless the guard is in place. This feature is essential for preventing accidental start-ups during maintenance.

Two-hand control (enabling switch devices) devices are particularly effective for keeping hands away from danger zones. These devices require the operator to use both hands to start the machine, which helps in avoiding accidental contact with moving parts.

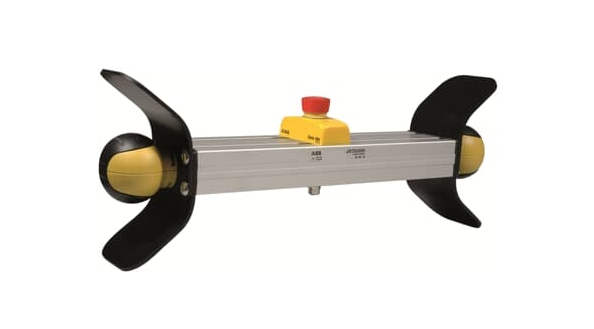

Emergency stop buttons are critical safety components. These buttons allow workers to quickly stop the machine in case of an emergency, preventing potential accidents. Ensure that emergency stop buttons are easily accessible and tested regularly.

Now, let's discuss additional components that enhance machine safety. Doors, locks & switches are essential for controlling access to hazardous areas. QuickGuard Aluminium Guarding and BlueGuard Stainless Steel Guarding provide durable and flexible guarding solutions. Barrier protection is crucial for keeping workers safe from moving parts and debris. Belt Conveyor Guarding ensures safety around conveyor systems. Panels and posts are used to create secure enclosures around machinery.

Troax provides comprehensive machine-safeguarding solutions that meet the highest safety standards. Their products include high-quality mesh panels, safety doors, and other components designed to create a secure working environment.

Remember, the goal of machine safeguarding is to protect workers and ensure a safe operational environment. Proper training and adherence to safety protocols are essential.

For more information on Troax safeguarding solutions and other safety tips, visit Proax.ca to contact our safety experts today.