Electrical safety in industrial environments requires more than basic protocols—it demands reliable systems that provide clear visual confirmation of electrical status. The REMLIVE RL-24i series from Fortress Safety addresses this critical need by offering technicians immediate, accurate information about electrical systems before maintenance begins.

The Role of Presence Of Voltage Indicators

The REMLIVE RL-24i Isolator Check provides the user with a positive check when isolating plant. It provides electrical isolation between the DIN rail unit and the door mounted display unit. This fundamental safety function eliminates dangerous assumptions about electrical status during maintenance procedures.

The door unit is designed to fit through the front of a control panel or switch so the user can see a live/isolation status. The super bright REMLIVE RL-24i display provides the user with a quick and easy method of proof of isolation in lock out / tag out procedures.

Isolator Check vs Phase Indicator – Main Differences

While both devices serve essential safety functions, they address different monitoring needs:

Isolator Check Features:

- Maximum Rated Current 20mA

- AC Voltages (50/60Hz) (Continuous) Min 24 Max 1,000

- DC Voltages (Continuous) Min 26 Max 1,000

- Multiple connection configurations including single phase, three phase, and neutral combinations

Phase Indicator Specifications:

- 3 Phase & Earth and 3 Phase, Neutral & Earth connections

- AC Voltages (50/60Hz) (Continuous) Min 24 Max 1,000

- Dedicated phase rotation monitoring with directional indicators

Voltage Handling and Safety Features

Both devices are engineered for demanding industrial environments. The input circuit is designed to withstand transient overvoltages according to measurement category IV. The equipment should not be subjected to transient overvoltage exceeding 8kV L-E.

Safety protection includes:

- The REMLIVE RL-24i has embedded 500mA fuse protection up stream of internal surge suppression

- For DC applications external 500mA Time Delay fuses rated to the voltage application shall be used

- Robust measurement category IV rating for industrial applications

| Feature | Isolator Check | Phase Indicator |

|---|---|---|

| Supports AC Applications | ✓ | ✓ |

| Supports DC Applications | ✓ | — |

| Maximum Current of 20mA | ✓ | ✓ |

| Built-in Fuse Link | ✓ | ✓ |

| Phase Rotation Detection | — | ✓ |

| Single Phase Monitoring | ✓ | — |

| Neutral Monitoring | ✓ | ✓ |

| Voltage Range (24V-1000V) | ✓ | ✓ |

Installing Remlive with Ease

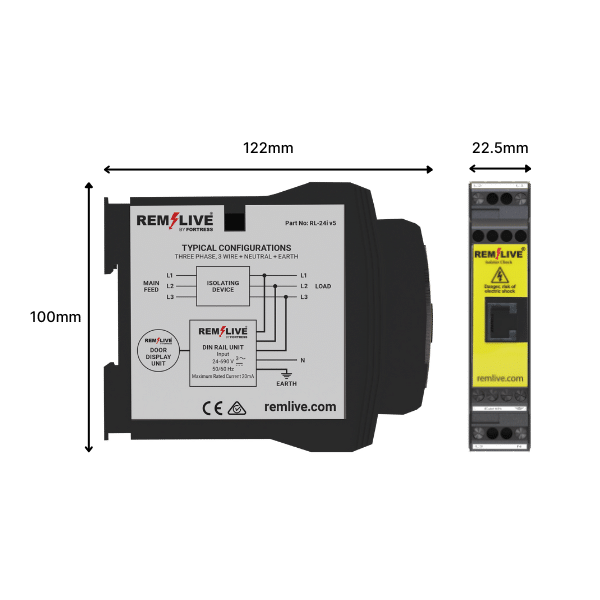

To mechanically install REMLIVE RL-24i simply clip the Main Panel Unit onto Din Rail (Top Hat). Fit Door Unit via 30.5mm hole, secure with locking nut and plug the RJ45 connector into the Main Panel Unit front fascia socket.

Installation requirements include:

- The equipment shall be connected to the supply using suitable wiring of at least 1mm2, with insulation rated to the voltage of the system being monitored

- A suitable disconnect device shall be installed in a location readily accessible and visible to the user

Dimensions:

- DIN Rail Module 22.5mm (W) x 100mm (H) x 122mm (D)

- Door Display Unit 30.5mm mounting hole diameter. The indicator unit itself measures 57mm (Deep) x 26mm (Rear Diameter) / 41mm (Front Diameter)

- Weight 232g total weight per RL-24i unit

Small Footprint, Strong Ingress Protection

The REMLIVE RL-24i series delivers maximum protection in a compact design. REMLIVE RL-24i is housed in a robust UL94 V-0 flame retardant enclosure, which has been selected for its durability and protective, insulation and zero halogen properties.

Protection specifications:

- REMLIVE RL-24i Door Unit has been designed to meet with IP66 requirements

- This equipment is tested and certified for use at ambient temperature between -35°C to 55°C and below 5000m altitude

Key Benefits of Remlive

The REMLIVE RL-24i series offers several critical advantages for industrial safety:

Enhanced Isolation Procedures REPLACE the REMLIVE RL-24i unit if EITHER of the two sets of TWO FLASHING INDICATORS FAIL TO FLASH ONCE A SECOND when a live supply is connected, unless they have been deliberately switched to the OFF position

Comprehensive Phase Monitoring The Phase Indicator provides detailed status information through its LED display system. The banks of two light emitting diodes at either side of the door unit will flash if the RL-24i Phase Indicator detects the correct cyclic phase rotation sequence.

Flexible Configuration Options Available configurations support diverse installation requirements, from simple single-phase monitoring to complex three-phase systems with neutral monitoring.

The REMLIVE RL-24i Isolator Check (part number RL-24i-IC-23) provides comprehensive voltage monitoring with up to 690VAC Cat IV configurations and compliance with IEC 60204 standards.

For phase sequence monitoring, the REMLIVE Phase Indicators are available in both Clockwise and Anti-Clockwise configurations, ensuring proper rotational verification for three-phase equipment.

These devices represent essential safety equipment for any facility where electrical maintenance occurs, providing the visual confirmation necessary to prevent accidents and ensure regulatory compliance. Through their robust design and reliable operation, they serve as critical components in comprehensive electrical safety programs.

Questions & Answers of Remlive

A presence of voltage indicator provides a clear visual indication that a circuit is live. This helps operators reduce the risk of exposure to hazardous voltage, improve electrical safety, and increase workplace efficiency.

The RL-24i Isolator Check alerts users to the presence of voltage, showing live indication immediately before isolating and no indication immediately after isolating. This makes it valuable for electrical isolation procedures.

While both devices look similar, they have different functions. The Isolator Check shows if a circuit is live, while the Phase Indicator confirms phase rotation and correct sequencing of electrical phases.

The Isolator Check supports AC and DC voltages up to 1000V. The Phase Indicator only supports AC voltage and does not support DC applications.

These devices are used in a wide range of industries, including power stations, coal mines, automated warehouses, nuclear facilities, and even particle accelerator sites.

They are designed to withstand transient overvoltages, include an embedded 500mA fuse link for surge protection, and have electrical separation between the DIN rail unit and the door-mounted display to keep dangerous voltages inside the cabinet.

Installation is quick and simple for a competent person following local electrical regulations. The DIN rail-mounted panel unit connects to the door unit using an RJ45 cable, with no special tools required.

The standard cable length provided is 1.4m, but the distance can be extended up to 10m using a standard RJ45 Ethernet patch cable.

The door unit is rated IP66 for high protection against dust and water, while the main panel unit should be installed inside an enclosure with an IP rating suitable for the environmental conditions of the site.

They provide clear, reliable visual confirmation of voltage presence or phase rotation, helping to prevent accidental contact with live circuits, improve isolation procedures, and minimise downtime.