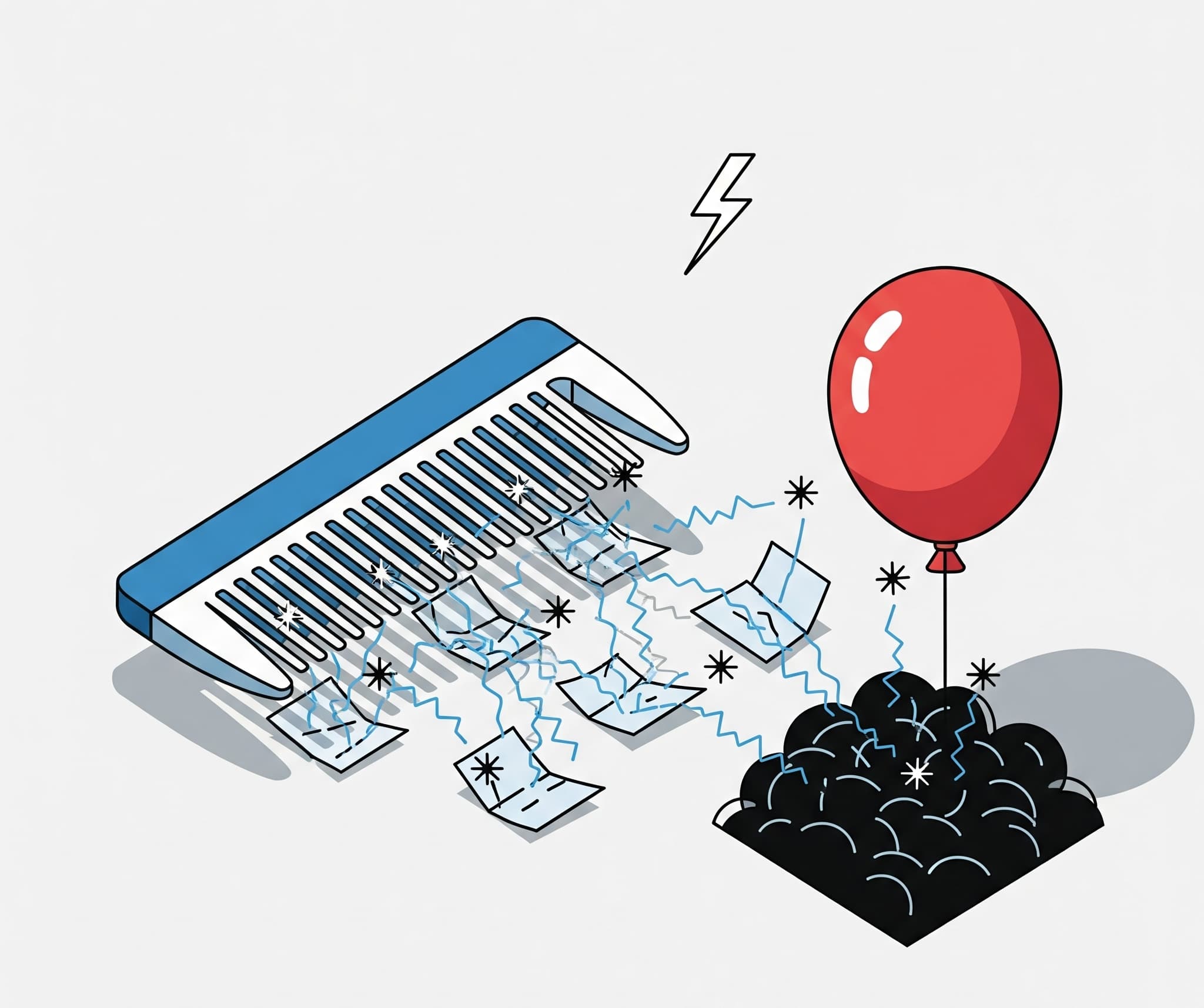

"I never thought static electricity could shut down our entire production line until it happened on a busy Tuesday morning"

That's how Sarah, a production manager at a leading Canadian electronics manufacturer, describes the day that changed everything. What started as minor dust issues on their circuit boards escalated into a $50,000 production halt when static discharge damaged an entire batch of sensitive components.

Sound familiar? You're not alone.

The Silent Saboteur in Your Facility

Static electricity doesn't announce itself with fanfare. It works quietly, accumulating charges that seem harmless until they're not. One moment your packaging line runs smoothly, the next moment films are sticking to everything, dust is clinging to products, and your quality control team is pulling their hair out.

We've seen it countless times at facilities across Canada. The frustrated maintenance technician who's tried everything. The quality manager dealing with customer complaints about contaminated products. The plant manager watching productivity metrics slide month after month, knowing something's wrong but not quite sure what.

Here's the truth: static electricity costs Canadian manufacturers millions annually in lost productivity, damaged products, and safety incidents. But it doesn't have to be this way.

Real Problems, Real Solutions

At Proax, we don't just sell equipment – we solve problems. As SMC's trusted partner in Canada, we've helped many manufacturers overcome their static challenges with proven pneumatic static control solutions that actually work.

When Packaging Lines Become Battlegrounds

Packaging facilities commonly lose 3-4 hours daily to static-related delays. Films cling to machinery, dust contaminates products, and teams constantly stop to clean equipment.

This challenge can be solved with SMC's IZS40 bar type ionizers positioned at key points along production lines. The solution eliminates those daily delays and allows teams to focus on production instead of fighting static.

Production managers implementing this solution report: "The difference was immediate. Line efficiency jumped 25% in the first month alone."

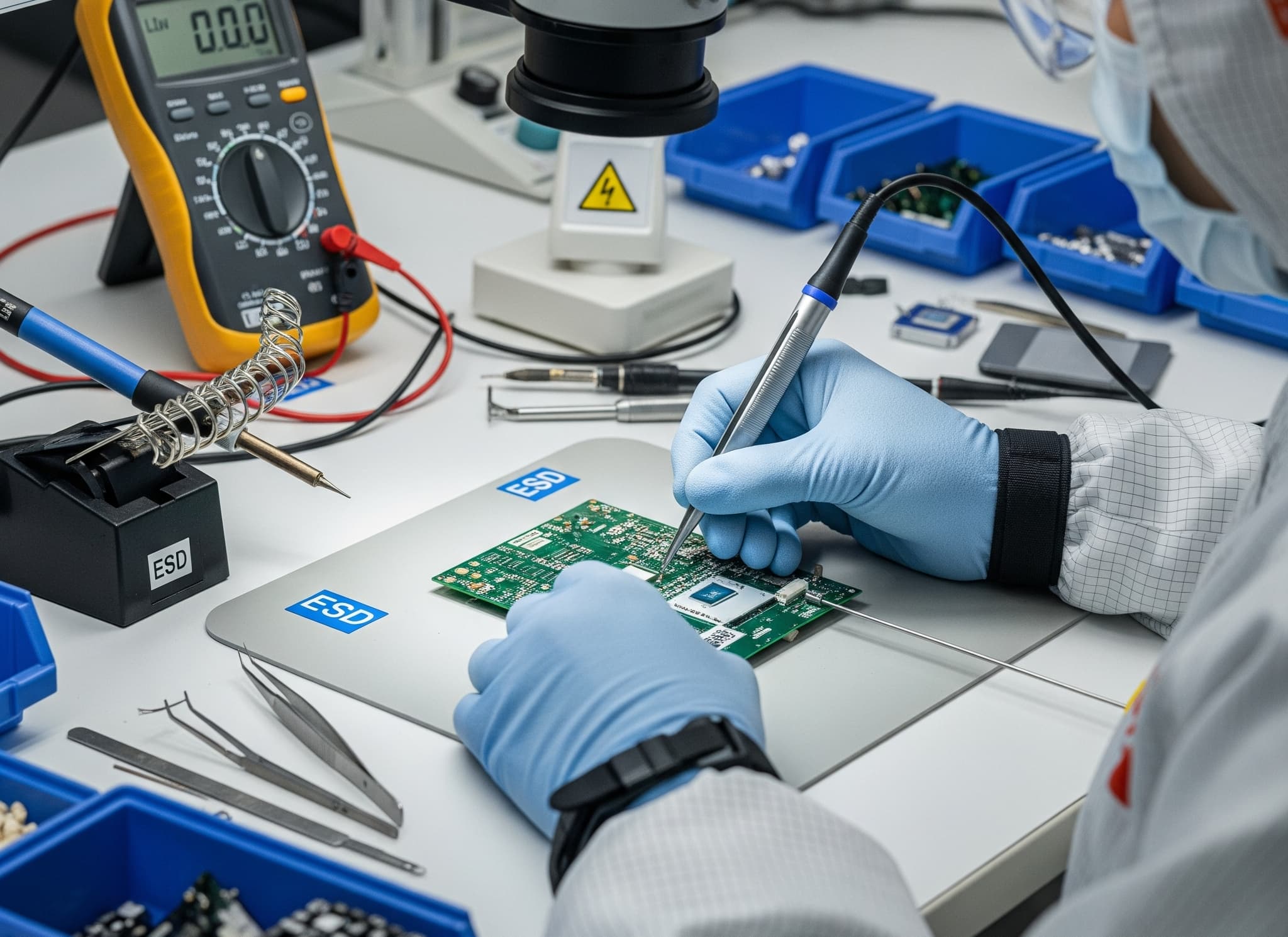

Electronics Manufacturing: Where Every Component Counts

Remember Sarah from our opening story? Her nightmare represents a common challenge in precision static control. The issue isn't just preventing future ESD damage but building confidence in quality systems.

This type of comprehensive challenge can be addressed using multiple ionizer types:

- Bar ionizers for wide-area coverage over circuit boards

- Nozzle ionizers for targeted component handling

- Static control sensors for real-time monitoring

Facilities implementing such comprehensive solutions can expect ESD-related defects to drop by up to 89%, while teams regain confidence and customers notice improved product quality.

The Printing Press Problem

Commercial printing operations face predictable challenges every winter. As humidity drops, presses start fighting back. Web materials stick, feeding becomes erratic, and print quality suffers.

This seasonal challenge can be solved with fan ionizers, specifically the SMC IZF10. These units provide the high-volume air flow needed to neutralize static on moving webs while preventing dust accumulation.

Operations managers implementing this approach report: "Now we actually look forward to winter. Quality is consistent year-round, and operators aren't constantly adjusting for static issues."

Beyond the Equipment: The Human Element

What sets Proax apart isn't just our access to SMC's industry-leading technology – it's our understanding that behind every static problem is a person trying to do their job well.

The Maintenance Manager's Toolkit

Maintenance professionals with decades of experience often encounter static issues that appear randomly across facilities. Traditional solutions frequently fail, and too much time gets spent troubleshooting instead of preventing problems.

These challenges can be prevented with gun type ionizers for spot treatment and ionizer guns for targeted cleaning. More importantly, proper static control principles can be implemented across the facility.

Maintenance teams using these tools report significantly fewer static-related requests, and when issues do arise, they know exactly how to address them using the right tools from comprehensive pneumatic static control solutions portfolios.

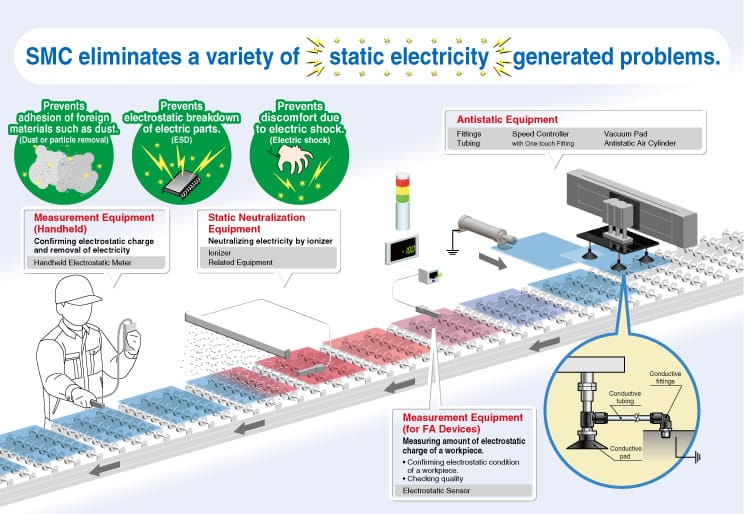

The Science Made Simple

You don't need a physics degree to understand static control, you just need the right partner. Here's what facilities learn:

Static builds naturally through friction, separation, and low humidity. In Canadian facilities, winter months create perfect conditions for static accumulation.

Different applications need different solutions:

- High-speed packaging lines benefit from bar ionizers with feedback sensors

- Precision work requires nozzle ionizers for targeted control

- Moving air applications work best with fan ionizers

- Maintenance teams need portable gun type ionizers for flexibility

Proper installation matters. Even the best ionizer won't work if it's positioned incorrectly or lacks proper air supply through quality fittings and tubing.

Why SMC Through Proax Makes the Difference

We could talk about technical specifications all day, but what really matters is results. SMC's ionizers don't just neutralize static – they do it reliably, efficiently, and safely. Our IZS electrode cartridges ensure long-term performance, while integrated sensors provide the feedback needed for optimal operation.

But equipment is only part of the equation. As SMC's elite distributor, Proax brings unmatched capabilities across Canada:

Nationwide coverage – 13 strategically located facilities from coast to coast, ensuring rapid response wherever you're located.

Technical excellence – In-house engineers at every location who understand both SMC technology and your specific industry challenges.

Innovation centers – 6 proof of concept centers where you can test solutions before full implementation.

Custom solutions – 4 design and build shops creating tailored static control systems for unique applications.

Local expertise – We understand Canadian manufacturing challenges, from humidity variations to regulatory requirements.

Comprehensive support – From initial assessment through product specification and ongoing technical support, we're your partner in static control success.

Take Action Today

Don't let static electricity continue costing your operation time, money, and quality. From bar ionizers for wide coverage to nozzle ionizers for precision work, we have the SMC solutions that solve real problems.

Contact our static control specialists for a free facility assessment and discover how quickly we can transform your manufacturing challenges into competitive advantages.