Compressed air systems rely heavily on effective filtration to maintain equipment performance and prevent contamination. Within pneumatic components, air filters play a crucial role in removing moisture, particles, and other contaminants from compressed air lines. One of the most important features in modern air filtration systems is the auto drain mechanism, which significantly improves system reliability and reduces maintenance requirements.

What is Auto Drain?

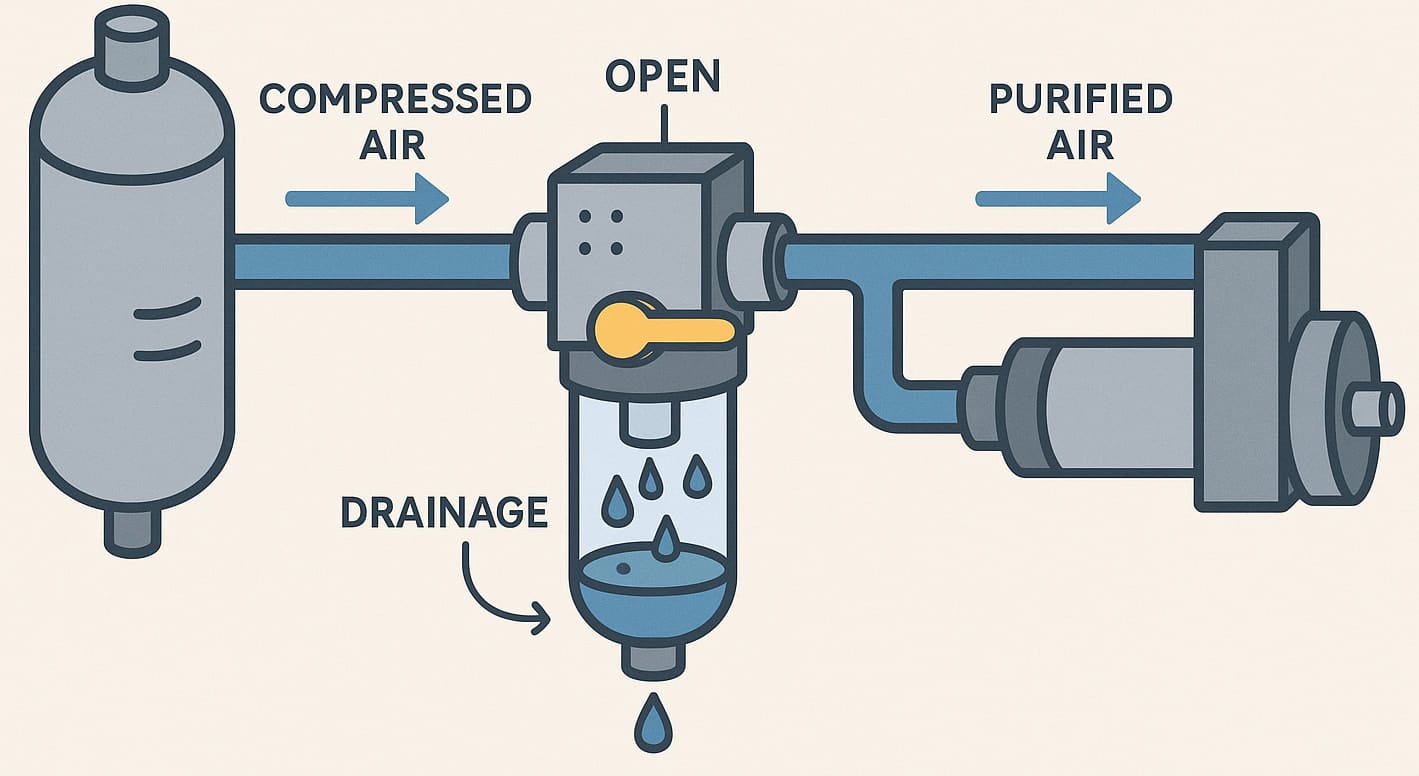

Auto drain is an automated condensate removal system integrated into pneumatic air filters and other airline equipment. When compressed air passes through filtration equipment, moisture naturally condenses and collects in the filter bowl along with other liquid contaminants. The auto drain mechanism automatically expels this accumulated condensate without requiring manual intervention or system shutdown.

The auto drain system typically consists of a float mechanism that opens a drain valve when condensate reaches a predetermined level. This allows water and other liquid contaminants to be expelled from the system while maintaining system pressure and continuous operation. Float-type auto drains are commonly available as air filter accessories for various filter series.

How Auto Drain Systems Operate

Auto drain equipped filters operate through a straightforward yet effective process. As compressed air flows through the filter element, contaminants are separated and fall into the collection bowl. When liquid condensate accumulates to a specific level, the float mechanism rises and activates the drain valve. The accumulated condensate is then expelled through the drain port while the system continues operating at full pressure.

Modern filter designs like the AF-D modular air filters incorporate transparent bowl guards on larger sizes, providing 360° visibility for monitoring condensate levels while protecting the bowl from environmental damage. This visibility is particularly valuable when combined with auto drain systems, allowing operators to verify proper operation.

Similarly, AFM-D modular mist separators benefit from auto drain functionality given their role in removing fine mist particles and aerosols that condense into liquid form. These units achieve 0.3µm filtration with 99.9% efficiency, making effective condensate removal essential for maintaining performance standards required in clean room applications.

Operation With Auto Drain vs. Without Auto Drain

With Auto Drain:

- Continuous Operation: Systems maintain uninterrupted compressed air flow while automatically managing condensate removal

- Pressure Maintenance: Full system pressure is maintained during drainage cycles, ensuring consistent air supply to downstream equipment

- Consistent Performance: Automatic condensate removal prevents accumulation that could compromise filtration efficiency or cause water carry-over

- Reduced Labor Requirements: Minimal manual intervention needed beyond periodic system inspection

- Enhanced Reliability: Eliminates human error factors associated with manual drainage schedules

Without Auto Drain (Manual Systems):

- Manual Monitoring Required: Operators must regularly inspect filter bowls to determine when drainage is necessary

- Scheduled Maintenance: Condensate removal typically requires either system shutdown or careful manual valve operation

- Potential Performance Degradation: Risk of condensate overflow that could contaminate downstream equipment

- Higher Labor Costs: More frequent inspection and manual intervention increases operational overhead

- System Vulnerability: Reliance on human operators following proper drainage schedules

Additional Equipment Requirements for Standard Manual Drain Systems

While manual drain systems may appear simpler initially, they often require supplementary equipment and procedures for optimal operation:

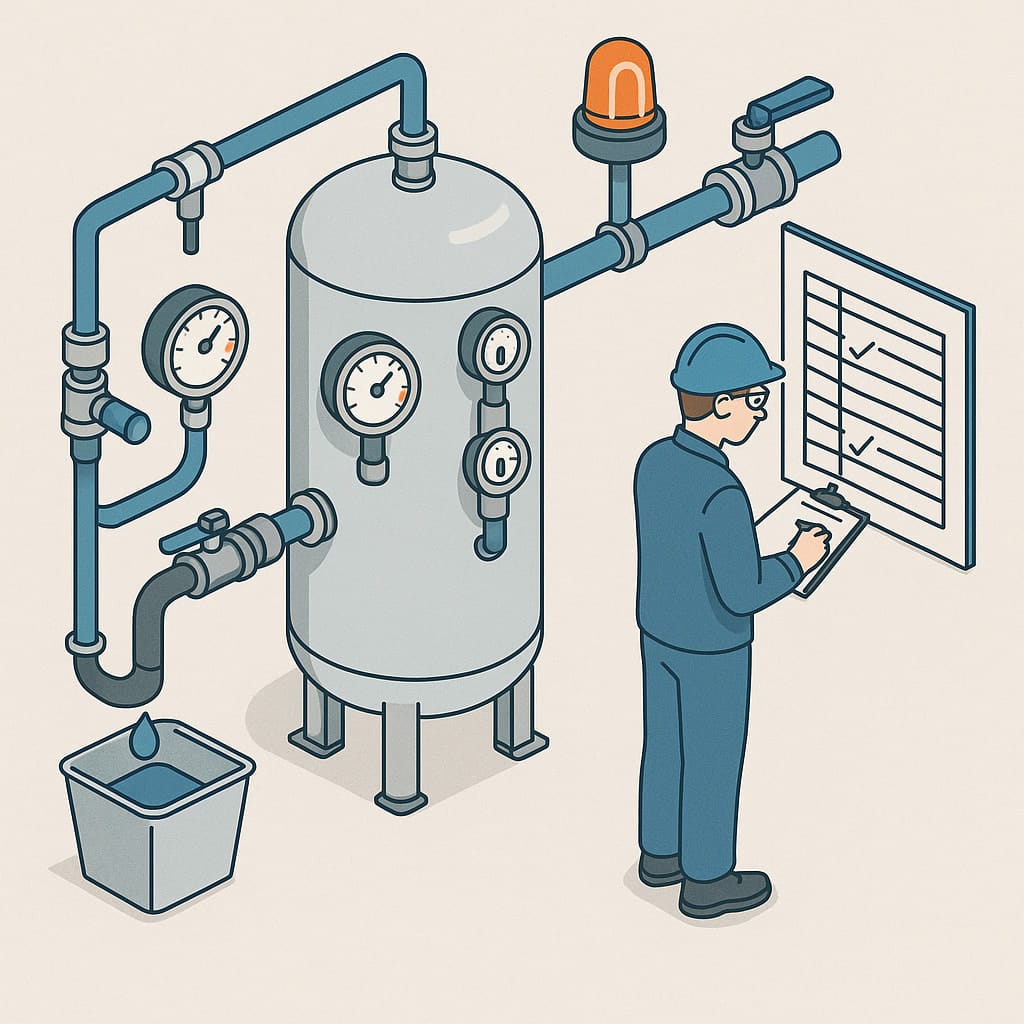

Drainage Infrastructure: Manual systems require proper condensate collection and disposal systems, including drain lines and collection vessels, particularly important in applications with environmental considerations.

Monitoring Equipment: Pressure gauges, visual level indicators, and alarm systems help operators maintain proper drainage schedules and identify potential issues before they impact system performance.

Isolation Components: Ball valves, isolation valves, or pressure relief systems may be necessary to safely perform manual drainage operations without complete system depressurization.

Maintenance Scheduling Systems: Documentation systems, maintenance schedules, and operator training programs become critical to ensure consistent condensate removal and prevent system contamination.

Enhanced Drain Valves: While basic manual drain valves are typically included, high-cycling applications may require premium drain valves designed for frequent operation and reliable sealing.

Applications and Selection Considerations

The choice between auto drain and manual drain configurations depends on several operational factors. Critical applications with continuous operation requirements typically benefit from auto drain systems, while applications with regular shutdown periods may effectively utilize manual drainage.

Auto drain systems prove particularly valuable in applications using multiple filter stages, such as combining standard air filters with mist separators for comprehensive contamination control. The modular design of modern filter series allows seamless integration of auto drain equipped units throughout the filtration train.

Cost considerations include both initial equipment investment and long-term operational expenses. While auto drain systems require higher initial investment, they often provide favorable return on investment through reduced labor costs, improved system reliability, and minimized risk of contamination-related equipment damage.

Conclusion

Auto drain technology represents a significant advancement in pneumatic air filtration, offering improved reliability, reduced maintenance requirements, and enhanced system performance. Whether implementing new filtration systems or upgrading existing installations, understanding auto drain operation and benefits enables informed decision-making that can improve both system performance and operational efficiency.

For applications requiring high reliability and minimal maintenance intervention, auto drain equipped filters provide clear operational advantages. However, proper system design, including appropriate drain infrastructure and monitoring capabilities, remains essential regardless of the drainage method selected.

Contact Us

Proax is SMC's Elite distributor and has been in the marketplace for over 60 years. We continue to grow and expand our product line and services to meet our customer's needs. Currently Proax has over 250+ employees with 13 branch locations coast to coast.

Our experienced team can help you select the right pneumatic air filtration solutions for your specific application requirements, whether you need auto drain equipped systems for critical applications or cost-effective manual drain configurations for standard use.

For assistance with pneumatic air filter selection, auto drain system specifications, or any questions about your compressed air filtration needs, contact us today. Our knowledgeable staff can provide personalized recommendations to optimize your system performance and operational efficiency.