Pneumatic system components rarely make headlines, but they're the workhorses that keep production lines running. The latest SMC AC-D Series modular FRL (Filter, Regulator, Lubricator) units deserve attention - they've raised the bar for what engineers should expect from these essential components. By solving persistent pain points that plague manufacturing floors, these units aren't just incrementally better - they fundamentally change how pneumatic systems can be designed and maintained.

The Journey from Basic Function to Engineered Excellence

When FRL units first entered industrial use decades ago, they served a straightforward purpose: clean the air, regulate the pressure, and add lubrication when needed. Early designs were functional but limited, often requiring specific orientations and offering minimal configuration options.

Over time, manufacturers like SMC recognized that these components weren't just utilitarian necessities but critical efficiency points in pneumatic systems. The AC series has steadily evolved, with each generation addressing pain points from the field.

The latest AC-D Series represents the culmination of this customer-driven development process. Let's examine what sets it apart from both its predecessors and competitors in the market.

Beyond Simple Updates: Design Philosophy Changes

What makes the AC-D Series different isn't just incremental improvement - it's a fundamentally different approach to modular pneumatics.

Visibility: A 360° Revolution

Previous generations of FRL units often made maintenance checks a hassle. Technicians would need to interrupt operations and sometimes even disassemble components to check oil levels or condensate accumulation.

The AC-D Series transforms this experience with its 360° visibility design. The transparent bowl guard allows for visual inspection from any angle, making it possible to quickly check condensate levels and remaining oil without interrupting operations. This might seem like a small change, but across hundreds of inspection points in a large facility, this visibility translates to significant time savings.

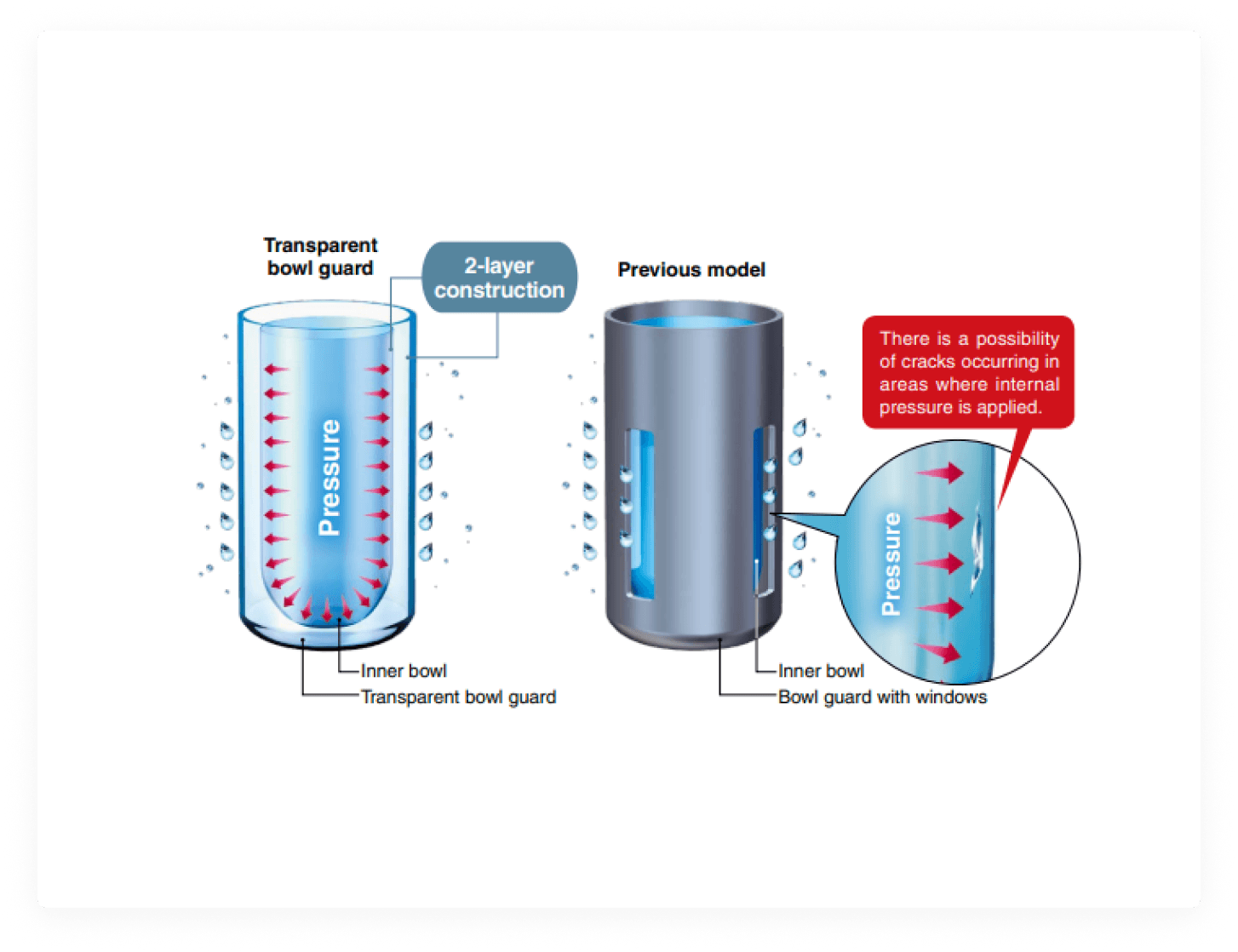

2-Layer Bowl Construction: Protection Meets Practicality

The new two-layer bowl construction represents an elegant solution to a longstanding challenge. Previous designs faced a tough compromise: either prioritize visibility with materials that were vulnerable to chemical damage, or use more resistant materials that obscured the interior.

The AC-D's innovative approach uses a transparent protective bowl guard covering a polycarbonate inner bowl. This prevents direct contact with corrosive chemicals and oil splash while maintaining full visibility. It's a perfect example of how thoughtful engineering can resolve seemingly contradictory requirements.

Modularity Reimagined

The term "modular" has been used in pneumatics for years, but the AC-D Series takes the concept to new heights.

Cross Adapter Integration: Multi-Dimensional Configuration

Traditional FRL assemblies were essentially linear, limiting system design options. The AC-D Series introduces a game-changing cross adapter that allows device connections in four directions: top, bottom, left, and right with spacer mounting.

This multi-directional piping configuration means engineers can now design pneumatic systems that work within their space constraints, rather than designing around the limitations of their components. For retrofits in particular, this flexibility can eliminate the need for costly infrastructure changes.

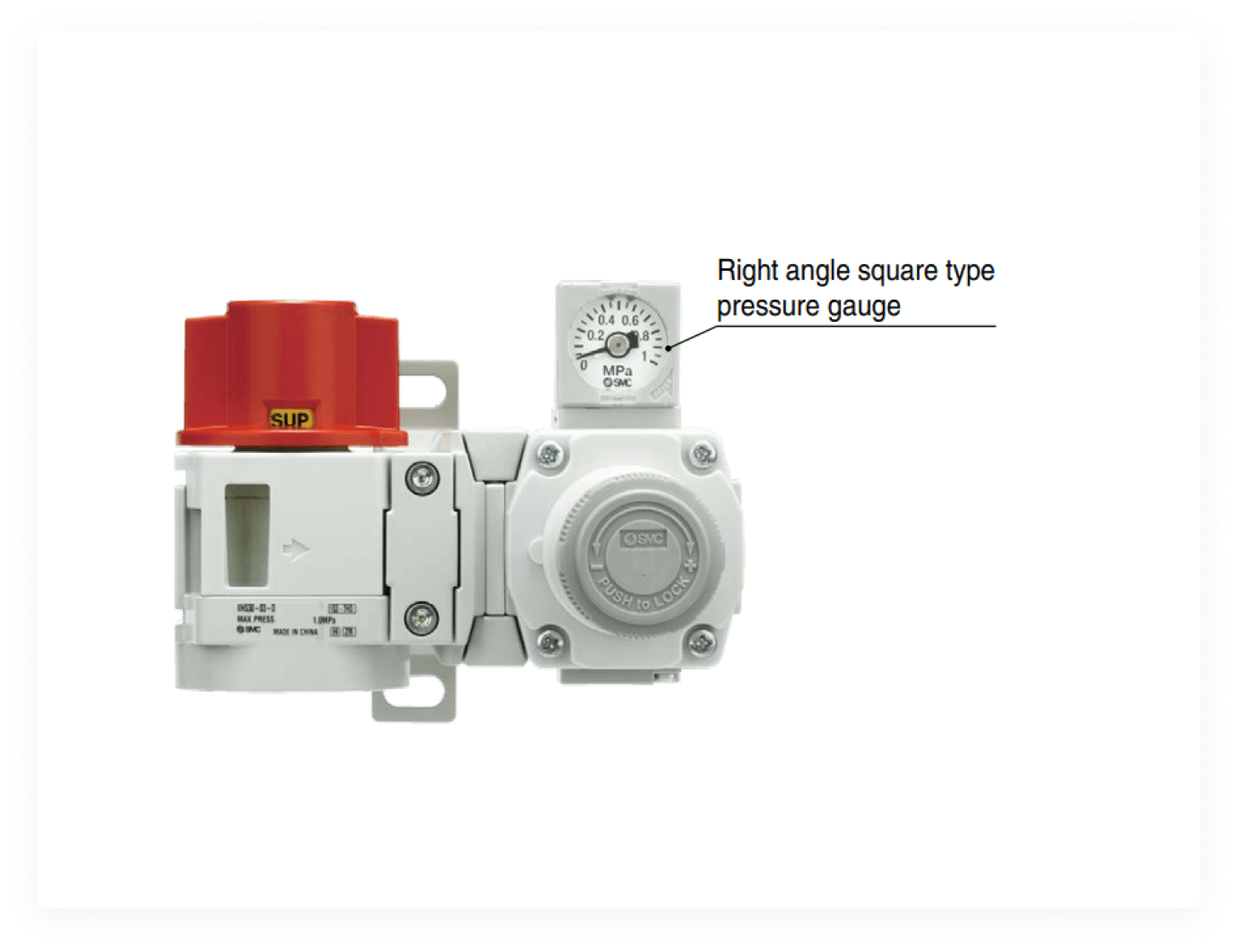

Right Angle Square Type Pressure Gauge: Information Where You Need It

Even the pressure gauge has been reimagined. The new square type pressure gauge can be adjusted in 90° increments, ensuring the scale plate faces the direction where it can be most easily read. This thoughtful detail demonstrates SMC's understanding that components aren't just installed once and forgotten – they're interacted with regularly by operators and maintenance personnel.

Practical Advantages in Real-World Applications

How do these design innovations translate to actual performance improvements? Let's consider some practical scenarios:

Scenario 1: Maintenance Efficiency

In a traditional setup, checking the condition of multiple FRL units might take a maintenance technician an entire shift. With the AC-D Series' improved visibility and orientation flexibility, the same checks can be completed in a fraction of the time, reducing both planned downtime and labor costs.

Scenario 2: Space-Constrained Installations

For machine builders working with tight cabinet spaces, the AC-D's compact design and flexible orientation options mean they can fit more functionality into less space. The cross adapter, in particular, allows for complex system configurations without the bulky manifolds or extensive piping that would otherwise be required.

Scenario 3: Challenging Environmental Conditions

Manufacturing environments can be harsh, with exposure to various fluids and chemicals. The dual-layer bowl construction of the AC-D Series provides significantly improved resistance to these challenges, extending component life and reducing replacement frequency.

Compatibility: Honoring the Past While Embracing the Future

One of the most practical aspects of the AC-D Series is its interchangeability with previous generations. The new series spacers can be used with older SMC components, making gradual system upgrades possible without necessitating complete replacement.

This backward compatibility demonstrates SMC's understanding that manufacturing facilities don't replace all their equipment at once – they evolve over time. The ability to integrate new components with existing infrastructure significantly reduces the barrier to adoption.

Cost Considerations Beyond the Purchase Price

When evaluating pneumatic components, many decision-makers focus exclusively on the initial purchase price. However, the AC-D Series illustrates why this approach can be shortsighted.

Consider these long-term value factors:

- Reduced Maintenance Time: The enhanced visibility and accessibility features translate directly to labor savings.

- Decreased Downtime: Faster service and maintenance mean production lines return to operation more quickly.

- Extended Component Life: The improved protective design means fewer replacements over the system's lifespan.

- Space Efficiency: More compact installations can free up valuable floor or cabinet space for other purposes.

- Configuration Flexibility: The ability to adapt to various installation requirements reduces custom piping needs and simplifies inventory management.

When these factors are considered holistically, the AC-D Series often provides a lower total cost of ownership despite a potentially higher initial investment compared to more basic alternatives.

Industry Trends and Future Directions

The innovations found in the AC-D Series align with broader industry trends toward more intelligent, efficient, and adaptable pneumatic systems. As manufacturing continues to evolve toward more flexible production models, components that offer versatility without sacrificing performance will become increasingly valuable.

We can expect future developments to further integrate digital monitoring capabilities, allowing for predictive maintenance based on actual usage patterns rather than scheduled intervals. The mechanical design improvements seen in the AC-D Series provide the foundation for these more advanced capabilities.

Conclusion: The New Standard in Pneumatic Preparation

The AC-D Series proves that listening to users and addressing their daily challenges can create more value than chasing technological novelty. SMC has set a new benchmark by focusing on what matters: visibility, flexibility, durability, and compatibility with existing systems.

For anyone managing pneumatic systems, the AC-D Series isn't just another component upgrade – it's a practical solution that pays dividends through reduced maintenance time, decreased downtime, and extended service life.

Whether you're starting fresh or upgrading gradually, these units deliver the rare combination of innovation that actually simplifies your work rather than complicating it.

Need help selecting the right AC-D Series configuration for your application? Our technical team is ready to assist with product selection and fast shipping on in-stock items. Contact us today to discover how the AC-D Series can improve your operations.