If you are working in the manufacturing industry and notice any of the following 5 signs within your production facility it might be time to look into how an industrial robot can improve your facility.

1. Labour Shortage

In Canada, small and mid-sized companies are experiencing widespread labour shortages. These small companies are the engine of the Canadian economy and without them, our current economic standing could very easily crumble.

Without an adequate amount of employees it is more than likely that your company cannot meet market demands and is suffering in the form of lost revenue as a result of low product yields and long lead times. Essentially, any owner or manager's worst nightmare.

If your company is struggling to fill or maintain a position it is most likely attributed by the current labour shortage and could easily be compensated with an industrial robot.

2. Reoccurring Safety Issues

According to the Bureau of Labor Statistics over 400,000 non-fatal injuries are reported annually from the manufacturing industry. In comparison, the retail industry has half as many workplace injuries each year.

Understanding why employees in the manufacturing industry would incur more injuries is not particularly difficult when looking at the responsibilities of each set of employees. Manufacturing personnel most often cite issues of fatigue, material handling, complacency, training and time as the primary reasons they incur injury.

Most of the time employees in the manufacturing industry are asked to work long shifts, completing repetitive tasks. The mix of long hours and dull work can lead to a lack of attentiveness that directly relates to a workplace injury. In many cases, it is not necessarily the employee's fault that an injury was incurred, but simply the nature of the job they are employed in.

3. Loss of Revenue due to Slow Production Times

While we might not like to admit it we have all experienced a time when we were completing a routine, repetitive task and later had a peer point out an error you had made. To which immediate embarrassment follows.

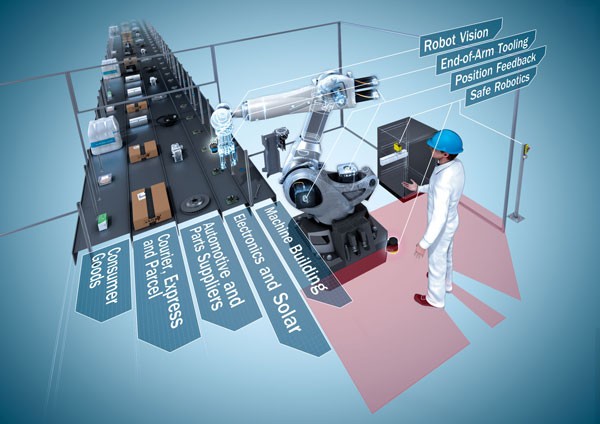

Manual configuration of products will inevitably lead to a margin of human error and slower production times. There are just no two ways about it. A small industrial robot can complete routine tasks faster than a human can and without the margin of human error.

If you need to shut down a line because you notice an error has been made halfway into your shift you risk losing a whole batch of products and significantly increasing the time it takes to get your products into your customers hands.

Don't get me wrong this isn't a reason to NOT report the error, but if this is routinely happening it might be time to consider automating parts of your production line with an industrial robot.

4. Noticeable Decline in Employee Morale

Employees who are stuck in dull and repetitive jobs are not only at a higher risk for incurring an injury, but they are more likely to be unhappy at work on a day to day basis. At this point you may be asking yourself as an employer why employee happiness is something you should be concerned with.

Well, in a round about way it's all linked. Research has shown that low levels of company morale can be linked to higher turnover rates, low productivity, and low profitability...Yikes

In the manufacturing industry it's easy for morale to be affected when you are working long hours in an non-stimulating position. The use of an industrial robot to take over an employee's position in a production line can improve employee morale if you are able to relocate that loyal employee to a new position with more responsibility.

It can be a sign of good faith to loyal employees to show reinvestment in their career which will simultaneously boost morale and increase productivity all around.

5. An Inability to Retain Top Talent

If your production facility is already being affected by the first sign in this article then an inability to retain top talent can truly squeeze your companies ability to perform.

Despite the fact that manufacturing jobs offer competitive compensation in comparison to positions requiring an equivalent skill level in the service sector, manufacturing businesses, especially SMBs, experience considerably higher difficulty when it comes to hiring new employees. Studies have shown that finding ways to automate your manufacturing facility can positively impact your ability to recruit and retain employees.

People want to be a part of a company that is at the cutting edge of technology. Implementing an industrial robot can help increase production yields and lead time, but it can also motivate your employees. A manufacturing facility that is considered innovative because of its use of technology is also thought of as successful. Prospective personnel want to know that the company they are choosing to work for aren't going to get left behind and are going to continue to be around for awhile. While they might not directly interact with the industrial robot the use of high-end technology can signify job security and longevity to many.

Conclusion

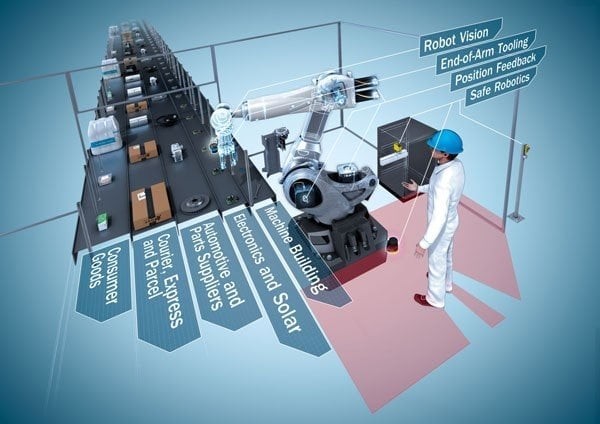

In our experience, our customers have seen drastic improvements to any one of the listed symptoms with the implementation of an industrial robot. The process of implementing an industrial robot in the manufacturing industry has the potential to be highly rewarding so it's important to identify the signs that might signify a change is needed in your facility early. It can also be even more important to identify the companies that can provide more than just a robot, but support, proof of concepts and end of arm tooling to expedite your robotics journey and make sure it runs as smoothly as possible.

Contact us today to explore how we can help your business thrive with the right automation solutions.