Every HR department and business owner in the manufacturing industry is facing the same seemingly insurmountable challenge: it’s increasingly harder to recruit workers and just as hard to retain them. And this reality is taken to a whole other level if your facility is even slightly remote or not easily accessible by public transportation. With plenty of jobs available in urban centers, candidates are spoiled with choices for their next job.

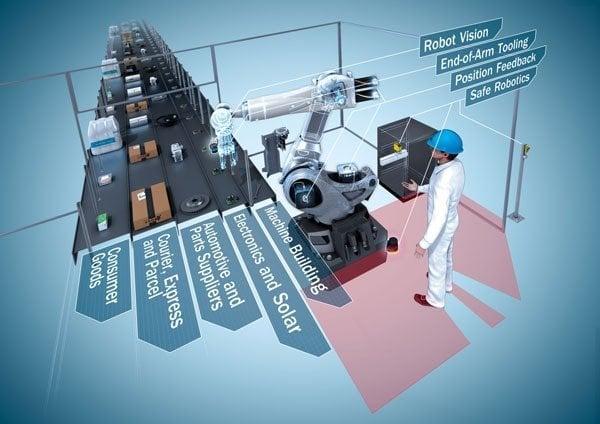

Faced with this reality, many businesses stakeholders have started to look at how increasing automation can help them compensate for the shortage of labor. In doing so, most businesses found that they were able to solve their personnel shortage problem and increase the quality of their recruits through the implementation of automation. Especially, in the cases where industrial or collaborative robots were implemented where it directly helped with recruiting efforts.

Here’s what we learned from our customers and partners that are experiencing this reality first-hand and adapting their business to keep the upper-hand in this socio-economic arm-wrestle.

A paycheck isn’t enough to attract or retain your best employees.

Despite the fact that manufacturing jobs offer competitive compensation in comparison to positions requiring an equivalent skill level in the service sector, manufacturing businesses, especially SMBs, experience considerably higher difficulty when it comes to hiring new employees. Why is that? According to a study by Edward L. Deci and Richard M. Ryan from the Department of Psychology of the University of Rochester, it all boils down to motivation. (Brace yourself… it’s a 268-page report!)

Motivation can be categorized into two main categories: extrinsic and intrinsic motivation. In the context of employment, the former is what’s usually listed in the compensation portion of your job offer. It’s, of course, an important factor your candidates will weigh in when considering your offer. However, there’s only so much you, as an employer, can afford to make the balance tip in your favour. Other companies, in different sectors, are also competing for the same candidates and entering a “who offers the biggest salary” tug of war, which can only be a viable solution for so long. Furthermore, if the only reason your candidate chose you over another company was the salary, chances are they’ll only be loyal to you for so long as there isn't be a higher paying job in sight.

On the other hand, intrinsic motivation, is what will keep people motivated in the long run.

It’s the pleasure you experience when quenching your curiosity. It’s the thrill you get when you first succeed at something new. It’s the empowerment you feel when trusted with new responsibilities. It’s what passion is made of. By introducing industrial robots in your facilities, you’re creating plenty of opportunities for your employees to tap into their intrinsic motivation. How? You’ll be creating a safer work environment where your employees can develop a greater sense of purpose, acquire new skills and become more autonomous. That, in turn, will promote higher-quality relationships and connection to others.

Investing in industrial robots will increase job security

Beyond enhancing production quality and allowing for increased productivity, investing in the modernization of your facility by introducing industrial robots should be perceived by your employees as your engagement to future-proof their jobs. Few companies are effective at promoting employer/employee interest alignment. By clearly communicating what challenges you are overcoming with the addition of the new robots, and how it will help you remain competitive in your industry you have an opportunity to position your company as a pioneer that embraces innovation enabling you to offer challenging and exciting careers with great employment conditions. Remember, job security is as important to your employees as staff security is for you. By having the interests of your employees at the forefront and putting your money where your corporate values are, you’ll be in a better position to earn your employees loyalty and devotion. That’s something money can’t buy.

Industrial robots in factories mean better jobs for your employees

Dull and repetitive tasks are at the complete opposite of what fosters intrinsic motivation. By delegating these tasks to robots and having your employees elevated to a role where they get to oversee or be responsible for the proper functioning of the application, you immediately elevate the average interestingness of the job. In addition to repetitive and dull tasks, chances are that some tasks in your plant have a high-risk factor. Sometimes, the potential danger is obvious, ie feeding glowing-red material to a 50-ton press. In most cases, the danger is hidden in seemingly banal routine tasks. Overextension injuries are related to pulling, lifting, pushing, holding, carrying and throwing activities at work. According to the US National Safety Council, overextension is not only the most frequent type of injury representing over a third of all work-related injuries, it’s also the most expensive for employers. Many of the tasks that exert a physical strain on your employees can be made safe by delegating it to an industrial robot or by accomplishing it in tandem with a collaborative robot - also known as a cobot. The second-most frequent cause of injuries in the work-place is slipping and tripping, which can sometimes lead to a fall. The probability of a employee incurring a workplace injury increases the more an employee has to walk around your facility and almost doubles when they are carrying an object.

Adding mobile robots to your “non-human staff” is a sure way to limit the incidence of injuries related to tripping or slipping while improving your profitability. Mobile robots are specifically conceived to transport objects, move racking elements, or pull small trailers thus freeing your employees so that they can accomplish higher-value and more gratifying tasks.

This project, realized by DGT Solutions Inc. represents a good example where a robot is used to complete a very simple and repetitive task that, when performed by a human, can take its toll on the body. The worker is now free to contribute to other value-added - and much more interesting - tasks while overseeing the robot, his new assistant.

Two birds with one stone

Ultimately, your goal is to simultaneously make sure that your business continues to thrive and to keep your employees happy and safe. Although some people may fear that industrial robots will render humans unnecessary in the manufacturing industry, the reality is that in the vast majority of cases they really are a strengthening factor that benefits the competitiveness of the business and the well being of its employees.

Enhance your business competitiveness and ensure employee safety with the power of industrial robots. Contact us today to explore how we can help your business thrive with the right automation solutions.