Problems erupt, deadlines are approaching, and you are looking for a solution without knowing the problem. A scenario we know all too well. It’s the inescapable truth; problems are inevitable. However, with a little bit of planning and expert design, you can minimize risk while maximizing efficiency. A robot might be the solution you’ve been looking for.

The following article will aim to answer these following questions;

How to grow your business despite a shortage of skilled workers?

How to increase production quality, while keeping expenses down?

How to scale up production in a low-volume operation?

With a growing shortage of skilled workers becoming a greater concern, the need to automate an industrial facility becomes more compelling. The choice to automate a manufacturing facility is NOT directly linked to job loss, but is meant to be a TOOL where symbiosis can occur between a human and a machine. The process to automate production is a large undertaking and can be intimidating in nature. The difficulty is that there is no cookie-cutter solution for automating. Our technical experts understand that every solution is unique. Which is why we will work closely with your team to find the right solution to fit your needs.

3 Reasons why you should automate

The intended purpose of automating is to increase efficiency while maintaining a consistent quality of products. However, implementing robots has its benefits that are often overlooked:

Employee retention and recruiting. Employee retention is the name of the game, it is more important than ever to keep your employee's satisfied, especially in a time of labour shortage. By implementing robots to complete dull, tedious tasks it allows employees to accomplish more fulfilling work. Providing a sense of purpose and leaving a positive impact.

Marketable. Implementing robots into a business can be used as a marketing tool to show company growth and business capabilities. Especially during the age of the internet, customers can find your competitor with just a few clicks. Robots can instill confidence in your customers and employees that you'll be in business for the future. Providing a sense of security to earn their trust.

Flexible. Collaborative robots (Co-Bots) have the capability to be fully programmable with simple drag and drop programming software. In addition, the absence of safety fences minimizes space requirements, making it perfect for limited space applications. A co-bot has the unique ability to learn independently from it's user with artificial intelligent (AI) to detect product variation and perform corrective actions.

As a national distributor, our ability to work closely with their experts allows our team to successfully provide robotic solutions that make automating production both feasible and practical.

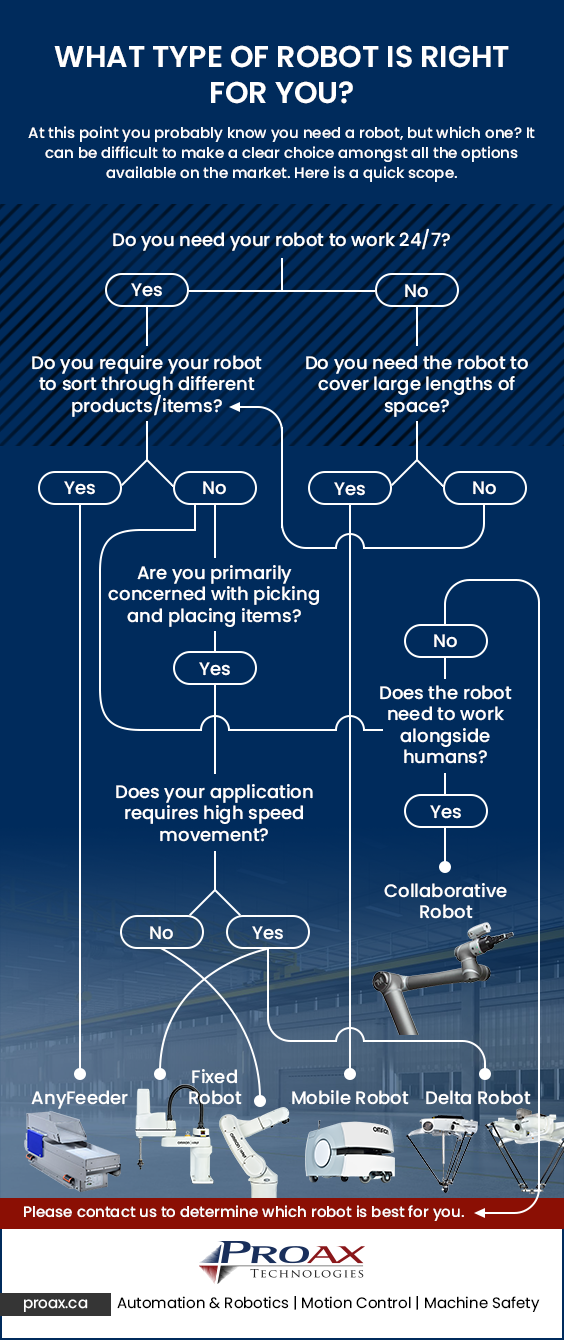

What Type of Robot Is Right for You?

Robots come in many shapes and sizes and can perform multiple tasks at varying degrees. However, not all robots are right for every application. For a successful implementation of robotic automation, it requires careful consideration of the task at hand. To help determine the right robot suited for your need, the infographic is provided below with helpful questions to consider.

What is the difference between an industrial robot vs collaborative robot?

Traditional industrial robots

Traditional industrial robots are a powerful tool used to automate control, with multipurpose functions and a wide range of motions. These robots are designed to fully automate production, removing human operators from harmful situations. Industrial robots have the benefit of a higher payload capability, a large range of speed capabilities and a higher return on investment (ROI). The increased payload capability and wide range of motion control mean industrial robots are large, heavy units that require safety measures such as; perimeter guarding and other safety equipment under ISO 13849-1/2 to safely operate. Traditional industrial robot aims to fully automate production whereas collaborative robots automate tasks for humans.

Traditional Industrial Robot

Collaborative Robots (Co-Bot)

Collaborative robots (Co-bot) are easily programmable and designed to work in collaboration with people with the use of sensing technology to detect humans in near proximity. Keeping humans safe while eliminating the need for large safety fences. Co-bots fulfill the need for skilled workers as the robot can perform multiple repeatable tasks and adapt to manufacturing variables. A co-bot uses 3D robot position guidance with advanced 2D vision technology to detect variations. Preventing quality spills and improving traceability. Co-bots are re-programmable units with a simple graphic user interface to allow for easy programming for new tasks, while artificial intelligent (AI) “remembers” previous tasks. Making switching between tasks seamless. Collaborative robots are perfect for a medium to low manufacturing facility with limited space.

OMRON Collaborative Robot

6 most common Co-bot applications:

- Machine tending. Loading and unloading parts of machinery frees up time for an operator to complete other tasks

- Pick and place. Delicate and precisely arranging object on an assembly line to feed into other machinery or organize multiple products on an assembly line in different tray’s

- Assembly. Simple parts assembly, freeing up time for workers to complete other complex and high precision tasks.

- Quality testing. Using vision detection to identify defective items that robots can then move off the conveyor belt.

- Palletizer. Robots can package goods or products onto a pallet. Reducing time and decreasing physical stress on workers

- Other application. Co-Bots can package, apply adhesives and complete other simple tasks. While the complex tasks will be left for human completion.

How to get started?

Understanding is the first step in automating production. The purpose of a robot is not to replace humans, but to work alongside them. Co-bots excel in completing simple linear tasks that are considered tedious or repetitive. Leaving employees, the freedom to perform other complex tasks to complete. Reducing lead time and increasing output.

To learn more about how Proax Technologies can help find a solution for you please directly contact us.