Official Distributor

Official DistributorSKU

MPN

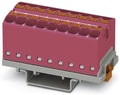

PTFIX 18X4-NS35-FE

Weight

0.022 kg

Series PTFIX

PTFIX 18X4-NS35-FE - Distribution block

Distribution block, Block with vertical alignment, nom. voltage: 800 V, nominal current: 32 A, number of connections: 18, connection method: Push-in connection, cross section: 0.2 mm2 - 6 mm2, mounting type: NS 35/7,5, NS 35/15, color: black/yellow

- Space savings of up to 50 % on the DIN rail, thanks to transverse mounting

- Time savings of up to 80 %, thanks to ready-to-mount blocks without manual bridging

- Time-saving conductor connection, thanks to tool-free Push-in direct connection technology

- Clear wiring, thanks to eleven different color variants

- Flexible use, thanks to DIN rail mounting, direct mounting or adhesive mounting

PTFIX

The Phoenix Contact PTFIX Series comprises ready-to-use distribution blocks featuring Push-in connection technology, designed to streamline potential distribution in control cabinets and various industrial applications. These blocks facilitate quick, tool-free wiring, enhancing installation efficiency and flexibility.

Key Features:

Ready-to-Connect Design: PTFIX blocks are pre-assembled and maintenance-free, allowing for immediate deployment without the need for manual bridging.

Push-in Connection Technology: This tool-free, direct plug-in method enables the easy insertion of solid and flexible conductors with ferrules, starting from 0.25 mm², reducing installation time.

Compact and Space-Saving: The compact design of PTFIX blocks saves space in control cabinets, making them ideal for applications with limited installation areas.

Versatile Mounting Options: Various adapters allow for DIN rail, direct, and adhesive mounting, providing flexibility to suit different installation requirements.

Color-Coded Variants: Available in up to 11 different colors, PTFIX blocks support intuitive and safe installation by enabling clear potential assignment.

Technical Specifications

General

| Note | Notes on operation the blocks can be bridged with one another via the conductor shaft, for corresponding plug-in bridges, see accessories |

| Number of rows | 1 |

| Number of Connections | 18 |

| Potentials | 1 |

| Nominal cross section | 4 mm² |

| Color | black/yellow |

| Insulating material | PA |

| Flammability rating according to UL 94 | V0 |

| Mounting Type | NS 35/7,5 |

| Rated surge voltage | 6 kV |

| Degree of pollution | 3 |

| Overvoltage category | III |

| Insulating material group | I |

| Maximum power dissipation for nominal condition | 1.02 W |

| Maximum Load Current | 41 A |

| Maximum total current | 63 A |

| Nominal current IN | 32 A |

| Nominal voltage UN | 800 V |

| Open side panel | No |

| General information | The maximum load current of a single clamping unit must not be exceeded. |

| Shock protection test specification | DIN EN 50274 (VDE 0660-514):2002-11 |

| Back of the hand protection | guaranteed |

| Finger protection | guaranteed |

| Result of surge voltage test | Test passed |

| Result of power-frequency withstand voltage test | Test passed |

| Power frequency withstand voltage setpoint | 2 kV |

| Result of the test for mechanical stability of terminal points (5 x conductor connection) | Test passed |

| Result of flexion and pull-out test | Test passed |

| Bending test rotation speed | 10 rpm |

| Bending test turns | 135 |

| Bending test conductor cross section/weight | 0.2 mm² / 0.2 kg |

| Bending test conductor cross section/weight | 4 mm² / 0.9 kg |

| Bending test conductor cross section/weight | 6 mm² / 1.4 kg |

| Tensile test result | Test passed |

| Conductor cross section tensile test | 0.2 mm² |

| Tractive force setpoint | 10 N |

| Conductor cross section tensile test | 4 mm² |

| Tractive force setpoint | 60 N |

| Conductor cross section tensile test | 6 mm² |

| Tractive force setpoint | 80 N |

| Result of tight fit on support | Test passed |

| Tight fit on carrier | NS 35/NS 15 |

| Setpoint | 5 N |

| Note | When aligning several blocks, it is recommended to either place a DIN rail adapter underneath the connection point or a flange element between the blocks. |

| Note | For versions with 6 or 7 connections, it is enough to place one DIN rail adapter centrally per block and place flange elements after every other block. |

| Note | When using the DIN rail adapter PTFIX-NS35, an aligned block must not protrude by more than a half. |

| Result of voltage-drop test | Test passed |

| Requirements, voltage drop | U1 ≤ 3.2 mV; U2 ≤ 1.5 x U1 |

| Result of temperature-rise test | Test passed |

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Short circuit stability result | Test passed |

| Conductor cross section short circuit testing | 4 mm² |

| Short-time current | 0.48 kA |

| Conductor cross section short circuit testing | 6 mm² |

| Short-time current | 0.72 kA |

| Result of thermal test | Test passed |

| Proof of thermal characteristics (needle flame) effective duration | 30 s |

| Result of aging test | Test passed |

| Ageing test for screwless modular terminal block temperature cycles | 192 |

| Oscillation, broadband noise test result | Test passed |

| Test specification, oscillation, broadband noise | DIN EN 50155 (VDE 0115-200):2008-03 |

| Test spectrum | Service life test category 2, bogie-mounted |

| Test frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Shock test result | Test passed |

| Test specification, shock test | DIN EN 50155 (VDE 0115-200):2008-03 |

| Shock form | Half-sine |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 130 °C |

| Static insulating material application in cold | -60 °C |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 28 MJ/kg |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

Dimensions

| Width | 28.6 mm |

| Length | 58.1 mm |

| Height NS 35/7,5 | 32.4 mm |

| Height NS 15 | 30.4 mm |

Connection data

| Connection Method | Push-in connection |

| Stripping length | 10 mm ... 12 mm |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross section solid min. | 0.2 mm² |

| Conductor cross section solid max. | 6 mm² |

| Conductor cross section AWG min. | 24 |

| Conductor cross section AWG max. | 10 |

| Conductor cross section flexible min. | 0.2 mm² |

| Conductor cross section flexible max. | 4 mm² |

| Min. AWG conductor cross section, flexible | 24 |

| Max. AWG conductor cross section, flexible | 12 |

| Conductor cross section flexible, with ferrule without plastic sleeve min. | 0.2 mm² |

| Conductor cross section flexible, with ferrule without plastic sleeve max. | 4 mm² |

| Conductor cross section flexible, with ferrule with plastic sleeve min. | 0.2 mm² |

| Conductor cross section flexible, with ferrule with plastic sleeve max. | 4 mm² |

| Two conductors with the same cross section, flexible, with TWIN ferrules, with plastic sleeve, minimum | 0.5 mm² |

| Two conductors with the same cross section, flexible, with TWIN ferrules, with plastic sleeve, maximum | 1 mm² |

| Connection cross sections directly pluggable | 0.5 mm² 6 mm² 20 10 |

| Conductor cross section solid min. | 0.5 mm² |

| Conductor cross section solid max. | 6 mm² |

| Conductor cross section AWG min. | 20 |

| Conductor cross section AWG max. | 10 |

| Conductor cross section flexible, with ferrule without plastic sleeve min. | 0.75 mm² |

| Conductor cross section flexible, with ferrule without plastic sleeve max. | 4 mm² |

| Conductor cross section flexible, with ferrule with plastic sleeve min. | 0.5 mm² |

| Conductor cross section flexible, with ferrule with plastic sleeve max. | 4 mm² |

| Internal cylindrical gage | A4 |

Ambient conditions

| Operating Temperature | -60 °C ... 105 °C (max. short-term operating temperature RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

Standards and Regulations

| Connection in acc. with standard | IEC 60947-7-1 |

Environmental Product Compliance

| China RoHS | Environmentally friendly use period: unlimited = EFUP-e |

| China RoHS | No hazardous substances above threshold values |

Accessories

Why Proax for Phoenix Contact 3273590?

Proax is an authorized distributor of Phoenix Contact 3273590 and one of Phoenix Contact's largest distributors in North America. Our highly skilled in-house technical team is ready to assist with any technical needs.

Have a question in mind? to help you get the right product as quickly as possible for your project. We're always here to help!

Short Lead Time

Highly Trained Staff

Live Chat

Technical Support

Local Inventory

60+ Years Experience

Additional Information

| Pack Size | 8 |

Recommended