3012302

Official Distributor

Official DistributorSKU

PHX3012302

MPN

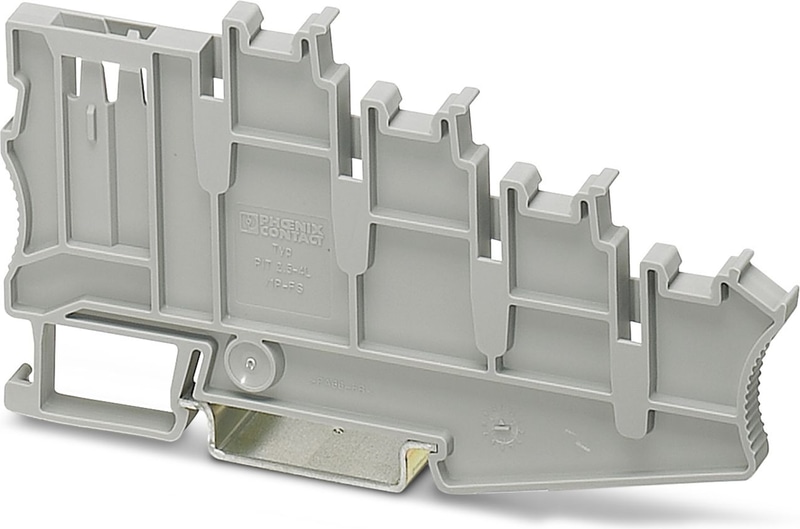

PT 2,5-4L/1P-FS

Weight

0.012 kg

Series PT

PT 2,5-4L/1P-FS - Flange

Flange, width: 5.2 mm, height: 105.6 mm, color: gray

- The compact design and front connection enable wiring in a confined space

- The Push-in connection terminal blocks are characterized by the system features of the CLIPLINE complete system and by easy and tool-free wiring of conductors with ferrules or solid conductors

- In addition to the testing option in the double function shaft, all terminal blocks provide an additional test pick-off

PT

The Phoenix Contact PT Series comprises feed-through terminal blocks that utilize Push-in connection technology, offering efficient and reliable wiring solutions for various industrial applications. These terminal blocks are designed for straightforward conductor insertion, enhancing installation speed and ensuring secure connections.

- Push-in Connection Technology: The PT Series employs a direct plug-in method, allowing solid conductors or conductors with ferrules to be inserted easily without the need for tools. This design facilitates quick and reliable wiring.

- Compact Design: The terminal blocks feature a space-saving form factor, making them suitable for applications where installation space is limited.

- High Electrical Ratings: Depending on the specific model, the PT Series terminal blocks can handle nominal voltages up to 800 V and nominal currents up to 32 A, accommodating a wide range of electrical requirements.

- Versatile Conductor Compatibility: These terminal blocks support various conductor types and sizes, providing flexibility in wiring configurations.

- Integration with CLIPLINE Complete System: The PT Series is compatible with Phoenix Contact's CLIPLINE complete system, allowing for standardized bridging, marking, and testing accessories, which simplifies inventory management and enhances system modularity.

Technical Specifications

Dimensions

| Width | 5.2 mm |

| End cover width | 2.2 mm |

| Height | 105.6 mm |

| Depth on NS 35/7,5 | 59 mm |

| Depth on NS 35/15 | 66.5 mm |

Material specifications

| Color | gray |

| Material | PA |

| Flammability rating according to UL 94 | V0 |

| Static insulating material application in cold | -60 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

Surge voltage test

| Result | Test passed |

Temperature-rise test

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 2.5 mm² | 0.3 kA |

| Result | Test passed |

Power-frequency withstand voltage

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

Mechanical strength

| Result | Test passed |

Attachment on the carrier

| Result | Test passed |

Test for conductor damage and slackening

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross section/weight | 0.14 mm² / 0.2 kg |

| Conductor cross section/weight | 2.5 mm² / 0.7 kg |

| Conductor cross section/weight | 4 mm² / 0.9 kg |

| Result | Test passed |

Aging

| Temperature cycles | 192 |

| Result | Test passed |

Needle-flame test

| Time of exposure | 30 s |

| Result | Test passed |

Oscillation/broadband noise

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Spectrum | Service life test category 1, class B, body mounted |

| Frequency | f1 = 5 Hz to f2 = 150 Hz |

| ASD level | 0.964 (m/s²)²/Hz |

| Acceleration | 0.58g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

Shocks

| Specification | DIN EN 50155 (VDE 0115-200):2022-06 |

| Pulse shape | Half-sine |

| Acceleration | 5g |

| Shock duration | 30 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

Ambient conditions

| Ambient Temperature (Operation) | -60 °C ... 105 °C (max. short-term operating temperature RTI Elec.) |

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

Accessories

Why Proax for Phoenix Contact 3012302?

Proax is an authorized distributor of Phoenix Contact 3012302 and one of Phoenix Contact's largest distributors in North America. Our highly skilled in-house technical team is ready to assist with any technical needs.

Have a question in mind? to help you get the right product as quickly as possible for your project. We're always here to help!

Short Lead Time

Highly Trained Staff

Live Chat

Technical Support

Local Inventory

60+ Years Experience

Additional Information

| Pack Size | 10 |

Recommended

PT 2,5-4PV BU - Multi-level terminal block, with equipotential bonder, nom. voltage: 500 V, nominal current: 18 A, number of connections: 8, number of positions: 3, connection method: Push-in connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: blue

PT 2,5-4PV BU - Multi-level terminal block, with equipotential bonder, nom. voltage: 500 V, nominal current: 18 A, number of connections: 8, number of positions: 3, connection method: Push-in connection, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: blue PT 2,5-3PV - Multi-level terminal block, with equipotential bonder, nom. voltage: 500 V, nominal current: 20 A, number of connections: 6, connection method: Push-in connection, 1st, 2nd and 3rd level, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray

PT 2,5-3PV - Multi-level terminal block, with equipotential bonder, nom. voltage: 500 V, nominal current: 20 A, number of connections: 6, connection method: Push-in connection, 1st, 2nd and 3rd level, Rated cross section: 2.5 mm2, cross section: 0.14 mm2 - 4 mm2, mounting type: NS 35/7,5, NS 35/15, color: gray