Selecting the right pneumatic fittings for your industrial system can make the difference between optimal performance and costly downtime. With so many options available, how do you navigate the complex world of thread types, materials, and sizing specifications?

At Proax, as an elite authorized distributor of SMC across Canada, we've guided countless engineers and maintenance professionals through this selection process. This comprehensive guide breaks down everything you need to know to make informed decisions for your specific application needs.

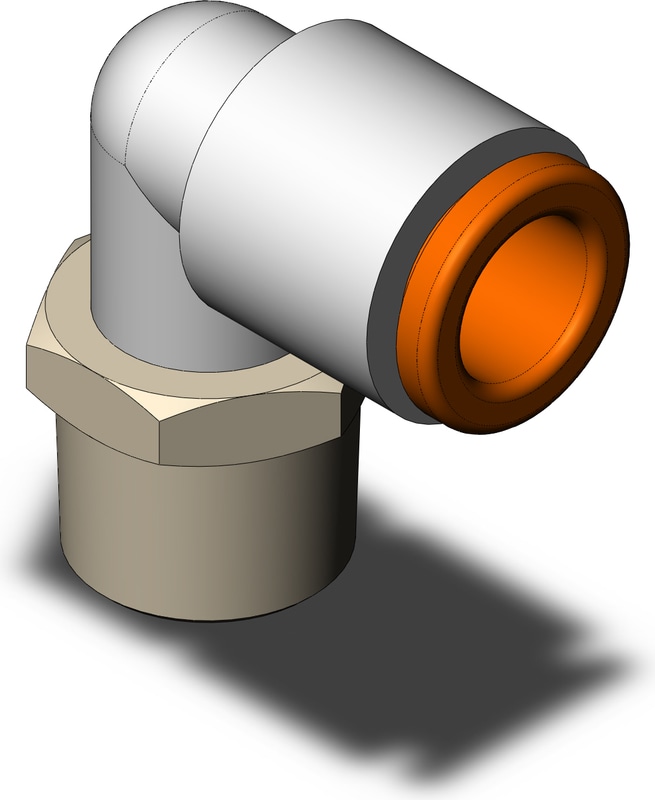

Choosing the Right Thread Type for Your Application

Thread compatibility is critical when selecting pneumatic fittings. Using incompatible threads can lead to leaks, connection failures, and system inefficiency. Here's a detailed breakdown of the most common thread types and when to use them:

Inch Thread Types

NPT (National Pipe Taper) - North American standard

- Perfect for applications requiring robust, leak-free connections

- Requires thread sealant or PTFE tape for proper sealing

- Commonly used in industrial and manufacturing environments

- Ideal when retrofitting older North American equipment

UNF (Unified Fine) - Precision applications

- Best suited for compact systems with limited space

- Provides highly precise connections

- Common in aerospace, automotive, and precision manufacturing

- Works well in applications requiring frequent disconnection/reconnection

Metric Thread Types

BSPP (British Standard Pipe Parallel) - European standard

- Uses O-rings or face seals for airtight connections

- Excellent for systems where components need frequent disassembly

- Common in European-designed equipment

- Preferred in applications requiring quick, tool-free assembly

BSPT (British Standard Pipe Taper) - Global applications

- Tapered design creates secure sealing under pressure

- Ideal for high-pressure systems

- Widely used in Asia and parts of Europe

- Good alternative when NPT fittings aren't available

M-Sized Threads (M5, M6, etc.) - Compact systems

- Perfect for space-constrained applications

- Compatible with global equipment standards

- Commonly found in robotics and compact automation systems

- Provides excellent vibration resistance

Universal Threads - Simplified Inventory

SMC offers universal thread fittings that accommodate both inch and metric standards, which can:

- Reduce inventory complexity

- Simplify maintenance and repairs

- Enable standardization across diverse equipment

- Save costs on specialized tooling

Material Selection: Finding the Perfect Balance

The environment your pneumatic system operates in significantly impacts which fitting material will perform best. Consider these options:

Metal Fittings

- Excellent corrosion resistance in standard conditions

- Durable with long service life

- Perfect for air and water systems

- Cost-effective for general industrial applications

- Operating temperature range: -20°C to 80°C

- Superior strength and chemical resistance

- Ideal for food processing, pharmaceutical, and chemical applications

- Perfect for washdown environments

- Resistant to extreme temperatures and harsh cleaning agents

- Operating temperature range: -65°C to 260°C

- Exceptional chemical resistance, even in aggressive environments

- Excellent thermal stability for high-temperature applications

- Ideal for semiconductor, analytical, or pharmaceutical industries

- Smooth internal surfaces to prevent contamination and ensure clean flow

- Operating temperature range: up to 200°C+

Sizing Guide: Ensuring Perfect Compatibility

Proper sizing ensures optimal flow rates, prevents pressure drops, and maintains system efficiency.

Tubing Dimensions Made Simple

When selecting fittings, match them precisely to your tubing's outer diameter (OD). Common equivalents between imperial and metric systems include:

- 5/32" ≈ 4 mm

- 1/4" ≈ 6 mm

- 5/16" ≈ 8 mm

- 3/8" ≈ 10 mm

- 1/2" ≈ 12 mm

SMC's KQ2 One-Touch Fittings make connections quick and secure, with clear size markings to prevent errors.

Thread Sizing: A Step-by-Step Approach

- Measure the thread diameter using calipers at the widest point

- Determine thread pitch using a thread gauge (number of threads per unit length)

- Identify thread type by comparing measurements to standard specifications

- Verify compatibility with your system's requirements

Pressure Ratings: Safety First

Always select fittings rated for your system's maximum operating pressure, plus a safety margin. Consider:

- Normal operating pressure

- Pressure spikes during operation

- Temperature fluctuations (which affect pressure ratings)

- Environmental factors that might stress connections

SMC Solutions: Innovation in Every Connection

SMC's extensive fitting lineup offers solutions for virtually any pneumatic application:

| Series | Features | Best For |

|---|---|---|

| KQ2 Series | Push-to-connect, compact | General purpose |

| KFG2 Series | 316 stainless steel | Harsh environments |

| KQG2 Series | Speed controller integrated | Compact automation |

| KR Series | Flame-resistant construction | High heat, flame risk |

These advanced fittings reduce installation time, improve reliability, and offer superior resistance to corrosion, temperature, and vibration.

Selection Checklist: Finding Your Perfect Fitting

Before finalizing your pneumatic fitting selection, consider these critical factors:

- System Requirements – Operating pressure, flow rate, and cycle frequency

- Environment – Temperature range, chemical exposure, and vibration

- Maintenance Needs – Frequency of disconnection and accessibility

- Compatibility – With existing equipment and components

- Budget – Initial cost vs. long-term reliability and performance

Why Choose Proax for Your SMC Pneumatic Fittings

As an authorized SMC distributor in Canada, Proax offers:

- Expert technical support to help you select the optimal fittings

- Comprehensive inventory across Canada for quick delivery

- Custom solutions for specialized applications

- Ongoing support for system optimization

Ready to Optimize Your Pneumatic System?

Selecting the right pneumatic fittings doesn't have to be complicated. Our team at Proax is ready to help you navigate the options and find the perfect solution for your specific needs.

Explore our full range of Pneumatic Fittings or contact us directly for personalized support.