Machine safety is a top priority for industrial operations - not just for regulatory compliance, but for creating a workplace where employees can operate equipment confidently. At Proax, we're proud to be an authorized Omron distributor, helping our customers find the perfect machine safety components for their specific needs. Let's dive into one of the most essential elements of any safety system: safety relays.

What Are Safety Relays and Why Do They Matter?

Think of safety relays as the brains behind your machine safety system. They take signals from devices like emergency stop buttons or safety laser scanners and make critical decisions about how your equipment should respond to potential hazards.

When a worker hits an emergency stop or breaks a light curtain beam, it's the safety relay that processes this information and ensures the machinery stops or switches to a safe mode of operation. Omron's safety relays are trusted across industries for their reliability and versatility.

Omron Safety Relay Options for Your Application

G9SE Compact Safety Relay Units

Space constraints in control cabinets? The G9SE series has you covered. These compact units pack powerful safety functionality into a slim design:

- Just 17.5mm wide - perfect for tight control panels

- Up to 3 safety outputs to control your equipment

- Choose between manual reset (requiring operator acknowledgment) or auto reset

- Easy-to-read LED status indicators that simplify troubleshooting

- Meets the highest safety standards: ISO 13849-1 (PLe) and IEC 61508 (SIL3)

Many of our customers use these compact units for monitoring emergency stop devices, door interlocks, and other single-function safety applications.

G9SA Advanced Safety Relay Units

For more sophisticated applications, the G9SA series delivers enhanced functionality:

- Expandable I/O capabilities for complex safety zones

- OFF-delay timer options for controlled stopping

- Advanced diagnostic features

- Flexible mounting options

- Suitable for integration with safety light curtains and other presence-sensing devices

These units excel in applications requiring precise timing control or multiple safety zones, such as robotic cells or packaging lines.

G9SX Flexible Safety Relay Units

The G9SX series represents Omron's most advanced safety relay technology:

- Logical AND/OR connections between units without extra programming

- Simple configuration of complex safety zones using just DIP switches

- Partial control of machinery with advanced muting capabilities

- Easy expansion to accommodate system growth

- Compatibility with a wide range of safety pilot devices

We've implemented G9SX units in everything from automotive assembly lines to food processing facilities, allowing for sophisticated safety control without the complexity of a fully programmable safety controller.

Selecting the Right Safety Relay for Your Application

When helping our customers choose the appropriate Omron safety relay, we consider several factors:

- Application complexity: Simple machine guarding or multi-zone protection?

- Space availability: Is control cabinet space at a premium?

- Required safety level: What Performance Level (PL) or Safety Integrity Level (SIL) must be achieved?

- Input devices: What safety components need to be monitored?

- Response requirements: Is standard stopping sufficient, or is controlled stopping needed?

For basic applications monitoring a single emergency stop device, the G9SE might be perfect. For a complex cell with multiple safety mats and safety edges, the G9SX offers the flexibility you need.

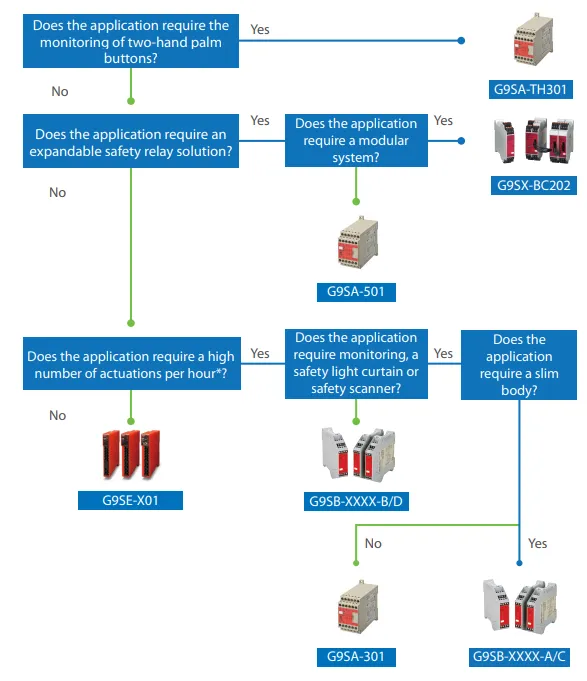

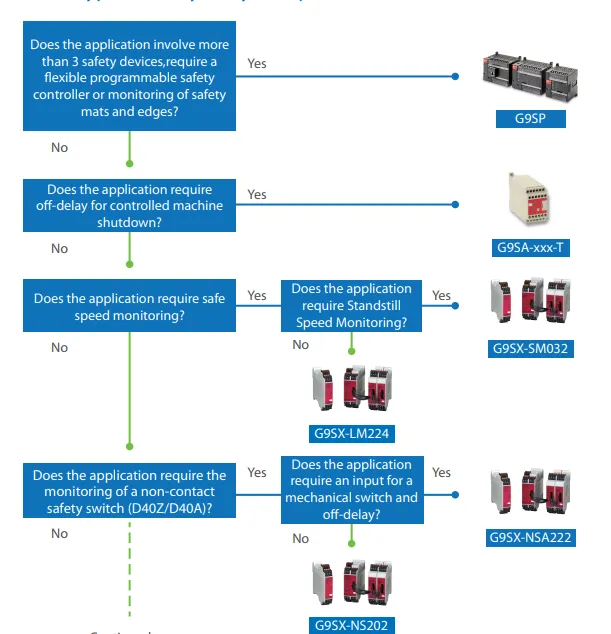

Omron Safety Relay Selection Guide

To make the selection process easier, Omron has developed comprehensive decision trees to guide you to the ideal safety relay for your specific application requirements:

This first decision tree helps you determine the appropriate safety relay based on your application's specific monitoring requirements. If you need to monitor two-hand palm buttons, the G9SA-TH301 is recommended. For applications requiring expandable solutions, you might need the G9SA-501 or the modular G9SX-BC202. Applications with high actuation frequencies may call for the G9SE-X01, while those monitoring safety light curtains or safety laser scanners might need the G9SB series.

The second decision tree addresses more complex applications. For systems involving more than three safety devices or requiring monitoring of safety mats and edges, a G9SP programmable safety controllers may be the best solution. Applications requiring off-delay for controlled machine shutdown would benefit from the G9SA series.

Integration with Complete Safety Systems

Safety relays are just one component in a comprehensive machine safety strategy. At Proax, we help customers integrate Omron safety relays with:

- Programmable safety controllers for the most complex applications

- Safety laser scanners for area protection

- Safety light curtains for point-of-operation guarding

- Feedback devices to monitor actual machine status

- Various safety accessories for complete system implementation

Ready to Improve Your Machine Safety?

Our team at Proax has the machine safety expertise to help you select, implement, and maintain the right Omron safety relays for your application. We understand that each manufacturing environment has unique challenges, and we're here to provide personalized solutions.

With TÜV certified in-house safety specialists across Canada in our 13 locations, Proax delivers local expertise with national coverage. Our safety experts can help assess your application requirements, recommend appropriate safety components, and ensure your implementation meets all relevant safety standards.

Contact us today to discuss your machine safety needs and discover how Omron's safety relay portfolio, available through Proax, can help you create a safer and more productive workplace.