The Power of Predictive Maintenance

- Respond faster to critical issues

- Reduce unplanned downtime

- Minimize maintenance costs

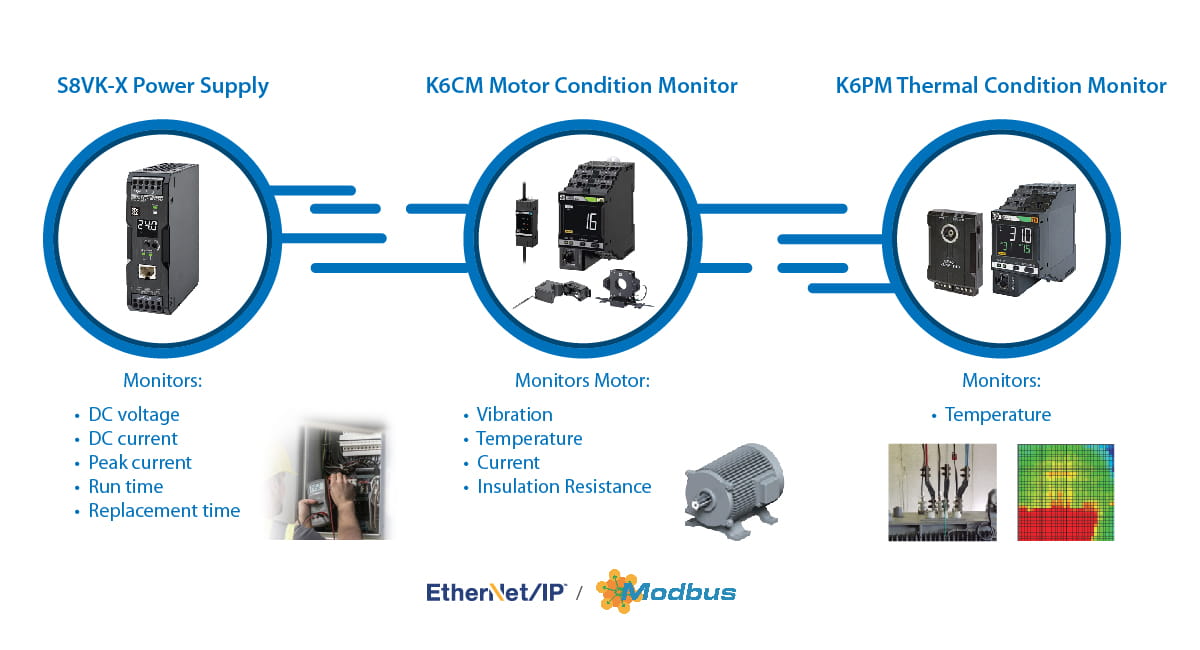

Omron's predictive maintenance devices allow multiple pieces of equipment to be monitored simultaneously using EtherNet/IP and Modbus TCP communication.

By implementing predictive maintenance solutions, manufacturers can achieve significant savings relative to traditional maintenance by reducing manual inspections.

Real-time monitoring of actual machine conditions can significantly reduce the number of unexpected and catastrophic failures by catching abnormalities sooner.

We offer several turnkey solutions equipped with Industrial Internet of Things (IIoT) capabilities that make it easy to continuously keep tabs on your power supply loads, motor condition, and equipment thermal condition.

This single-phase power supply detects abnormal DC load conditions and calculates remaining power supply life based on the power supply load conditions. Its user-friendly local display provides easy status visualization and can be monitored remotely with the included PC monitoring software.

Learn More About S8VK-XThis DIN-rail mounted controller monitors three-phase induction motors continuously to detect abnormal load conditions, bearing wear and insulation breakdown

The K6PM analyzes temperature deviation over time using thermal imaging sensors and detects abnormalities before they become serious. Its digital display and alarm bar allow operators of all experience levels to respond to issues.

Unplanned machine downtime is a huge headache for the business sector, as ongoing problems like aging infrastructure, skilled worker shortage, and recent societal disruptions drive up operational costs by reducing equipment availability. Fortunately, advances in sensors, analytics, and communication technologies are making predictive maintenance increasingly practical and affordable for small, medium, and large manufacturing companies. This white paper examines four use cases that demonstrate the power of a predictive maintenance strategy.

Download white paper