Tool Changers

Tool changers enable your robots to automatically switch between different end-effectors, grippers, and tools, maximizing productivity and flexibility. Proax supplies manual, pneumatic, automatic, and magnetic tool changers from Zimmer Group and other leading manufacturers. Stock items ship same-day across Canada, with short lead times on special orders. Free pickup available at all 13 Canadian locations.

Series

WPR5000 Pneumatic Tool Changers

WWR1000 Series Tool Changers

WER1500 Electrical Energy Elements

WER3000 Pneumatic Energy Elements

WER3000 Communication Energy Elements

WER4000 Fluidic Energy Elements

WER3000 Fluidic Energy Elements

WER3000 Communication Energy Elements

WER4000 Pneumatic Energy Elements

WER4000 Electrical Energy Elements

Why Tool Changers?

One robot, multiple tasks. Tool changers eliminate manual changeovers and enable your automation system to handle diverse operations—from welding to assembly to material handling—without investing in multiple robots.

- Manual – Up to 40kg capacity, operator-actuated, cost-effective

- Pneumatic – Up to 500kg+ capacity, fully automated, high-frequency changes

- Manu-matic – Up to 29kg capacity, works without air supply

- Magnetic – FDA-compliant, hygienic design for cleanroom applications

All systems follow ISO 9409-1 standards for universal robot compatibility with ABB, FANUC, KUKA, Yaskawa, Universal Robots, and more.

Quick Selection Criteria

Payload capacity - Match to your heaviest tool + workpiece weight

Change frequency - Manual for occasional, pneumatic for high-frequency

Media requirements - Pneumatics, electrical, vacuum, communication protocols

Environment - Cleanroom rating, IP protection, FDA compliance

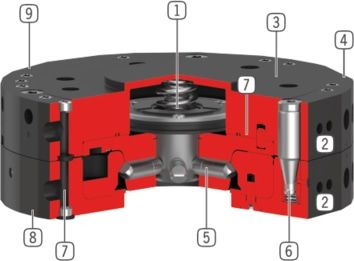

WPR5000 Tool changers

Drive – Spring-preloaded piston with self-locking system. Holds tools securely even during pressure loss or emergency stop.

Mounting for Energy Element – Lateral connection for optional WER modules supporting pneumatic, vacuum, hydraulic, electrical, and communication transfer.

Robot Flange – Mounting pattern compliant with EN ISO 9409-1.

Piston Position Sensing – Optional integrated sensors save space and reduce external interference.

Locking Bolt – All locking components made of hardened steel for strength and durability.

Centering Pins – Preloaded design provides high torsional rigidity and accurate positioning.

Integrated Air Feed-Through – Enables air or vacuum transfer for hoseless control.

Loose Part – Tool-side unit for customer installation.

Fix Part – Robot-side assembly component.

Frequently Asked Tool Changer Questions

They're the same thing. Tool changer, quick changer, and coupler are interchangeable terms for devices that enable quick robot tool connection and disconnection.

Pneumatic tool changers complete changes in 1-3 seconds. Manual systems take 5-15 seconds. Manu-matic systems with tool racks change in 2-5 seconds.

Yes. Select a model matching your cobot's ISO 9409-1 flange size and payload capacity. Magnetic and lightweight pneumatic changers are popular for collaborative applications.

Quality pneumatic tool changers feature spring-loaded locking mechanisms that maintain grip even during complete pressure loss. The tool remains securely locked until pressure is restored and an unlock signal is given.

Calculate your heaviest tool weight plus maximum workpiece weight, then add 20-30% safety factor. For example: 8kg tool plus 15kg workpiece = 23kg. With 30% safety factor, you need approximately 30kg capacity. Always round up to the next available size.