The saying “it is better to be safe than sorry” has never been more true than with the rapid increase of automation in the Canadian workplace. It has never been more vital to protect the product and protect the people than today. Implementing machine automation in a facility enables the manufacture to produce higher quality products both consistently as well as at a faster rate. Minimizing defective products and preventing the waste of valuable resources saves both money and time. Machine automation, however, poses new safety concerns for Canadian facilities, but these can be easily preventable with the use of machine safety fencing.

Why Do You Need Safety Fencing?

The global outbreak of the coronavirus pandemic shows the dangers lurching around the corner. It is more important than ever to invest in the safety equipment to ensure the safety of your employees from harmful bacteria, viruses, and machinery.

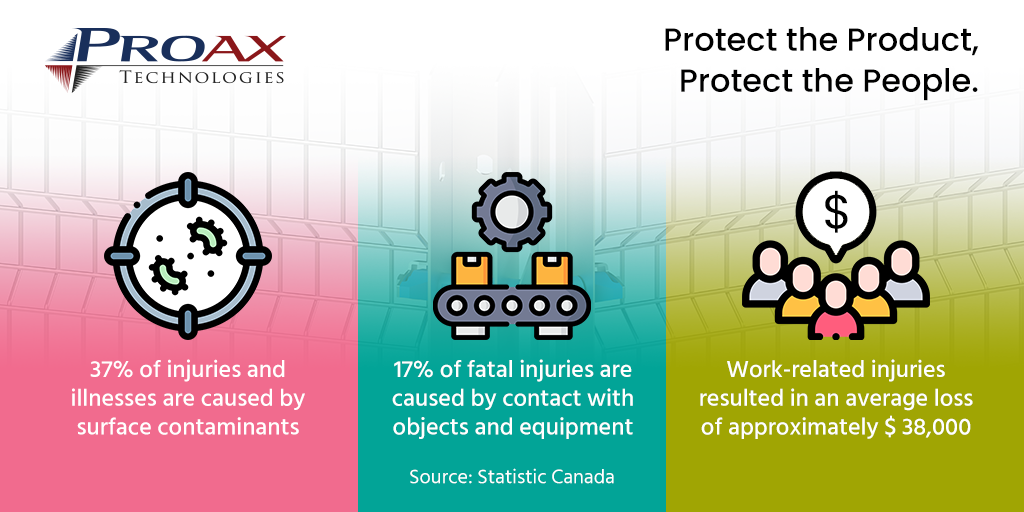

Safety fencing is essential for the protection of your equipment and employees. Safety fencing will prevent unnecessary downtime and avoid costly mistakes. But more importantly, it protects your employees. In a study conducted by the national safety council, on average workplace-related injuries results in a loss of approximately $38,000. Includes wages, downtime, and medical expenses. While harmful bacteria or viruses cause approximately 37% of all injuries and illnesses, 17% of fatal injuries are caused by contact with objects and equipment.

5 Benefits of Troax Blueguard Safety Fencing

- Ease of install/ modularity- To complete your safety solution, we offer a product that anyone can install and is hygienic.

- Robustness and longevity- Our machine guarding system is designed and produced in accordance with the standards of ISO, CSA, and meets the requirements of the European Machinery Directive.

- Low Maintenance- Our stainless steel machine guarding is designed for high jet sanitation while still providing the highest level of security.

- Traffic management- This perimeter guard is robust, and the modular design allows modification to any configuration ensuring safe distance to hazard requirements.

- Security and Safety- In addition to added safety, Blueguard perimeter guard is compatible with many safety switches.

5 safety fencing considerations

- The area requiring guarding (safe distance to hazard) - How large is the area you want to protect?

- Height of the fencing (reach over) - How high will you require the machine fencing?

- Operator Safety- How will authorized personal gain access to the machine in the cell?

- Maintenance- Will the safety fencing be under stress from chemicals during washdown or in proximity to the heavy forklift or pedestrian traffic?

- Special requirements- Are there any special requirements for your application? Do you need cutouts for conveyors, mounting of enclosures, or safety products such as light curtains or area scanners? Do you require a non-contact, keyed, or solenoid safety switch at the gate?

4 Different Types of Panel Options (hygienic and Non-Hygienic)

- Mesh Panels- durable and lightweight designs allow for simple customization and quick installation while maintaining visibility without compromising strength. It can be used in non-hygienic areas.

- Polycarbonate Panels- ensures a protective solution with the containment of particulates to one location while continuing to provide visibility and durability for sanitizing.

- Full Steel Panel- high-level protective solution for welding or unwanted personnel from accessing a particular area while providing a simple solution for maintaining production.

- Stainless steel - offers a hygienic and robust solution for the Canadian marketplace.

Discover the protection Troax's machine guarding products offer against harmful machinery and contaminants. Ensure the safety and hygiene of your workplace today. For more information, head to our contact us page and get in touch. Your safety is our priority!