Industrial contactors are essential in modern automation, but choosing the right one can be daunting. In this guide, we’ll simplify contactor selection, maintenance, and troubleshooting to keep your operations running smoothly. Learn the best practices to enhance safety and efficiency.

What Are Industrial Contactors?

A contactor is an electrically controlled switch used for switching power circuits, especially in industrial applications requiring high current capacity. Contactors are crucial in situations where electrical load control is needed, such as motor operations or heavy machinery.

Key Differences: Contactors vs. Relays

| Aspect | Contactors | Relays |

|---|---|---|

| Load Capacity | High (e.g., motors) | Low (e.g., control circuits) |

| Main Application | Switching large currents | Signal control |

| Safety Features | Overload and short-circuit protection | Basic insulation |

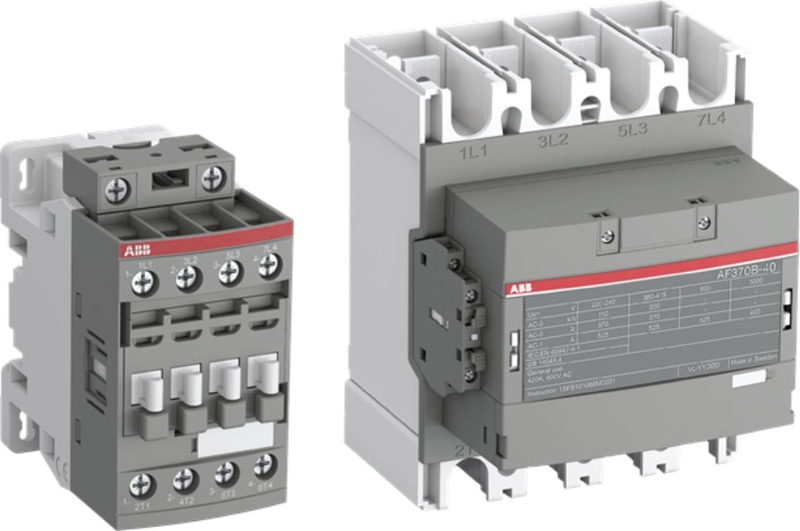

Types of Industrial Contactors

At Proax, we provide a wide range of contactors to suit various industrial applications. Here’s an overview of our offerings:

3-Pole Contactors

For motor starting and power switching. Ideal for protecting motors from overload.

4-Pole Contactors

Suitable for power switching applications. Offers reliable control for auxiliary circuits.

Contactor Relays

Used for switching control and auxiliary circuits. Compact and efficient design for multiple applications.

Contactors for Capacitor Switching

Designed to withstand unlimited peak current. Ensures safe and reliable capacitor control.

Contactors for DC Switching

Efficiently manage DC load switching. Compact design for space-saving installations.

Contactors for Safety Applications

Help make your system safer with reliable safety features. Ideal for environments with high safety standards.

Installation Contactors

Ensure hum-free control for quieter operations. Suitable for building automation and residential applications.

Definite Purpose Contactors

Combine flexibility with high performance. Suitable for various industrial applications.

ABB CR460 Lighting Contactors

NEMA Lighting Contactors: Mechanically and electrically held for commercial and industrial lighting control. Ideal for complex lighting systems in large facilities.

ABB CR360L Lighting Contactors

Mechanically and electrically held for reliable lighting control.

ABB CR160 Lighting Contactors

Designed for heavy-duty lighting control in industrial environments.

How to Choose the Right Contactor

Step 1: Determine Load Requirements

Consider voltage, current, and application type to select the appropriate contactor.

Step 2: Safety and Compliance

Ensure CSA and UL certifications to meet industrial safety standards.

Step 3: Consider Environmental Factors

Evaluate conditions like dust, moisture, and temperature.

Step 4: Select Features and Accessories

Choose overload relays, auxiliary contacts, and suitable enclosures to enhance safety.

Installation and Maintenance Tips

Installation Steps

- De-energize the circuit.

- Follow the wiring diagram carefully.

- Use appropriate tools for secure connections.

Maintenance Best Practices

- Periodically clean contacts to prevent corrosion.

- Inspect for overheating and replace worn components.

- Tighten loose connections regularly.

Troubleshooting Common Issues

- Buzzing Noise: Check coil voltage and secure connections.

- Frequent Tripping: Inspect for overload or short circuits.

- Contact Welding: Install surge protection to avoid this issue.

FAQ Section

- Q: What’s the difference between NO and NC contactors?

- A: NO (normally open) contacts close when the coil is energized, while NC (normally closed) contacts open.

- Q: How do I know if a contactor is failing?

- A: Look for buzzing noises, overheating, or inconsistent operation.

- Q: Can contactors be used for DC switching?

- A: Yes, but specialized DC contactors are required.

Need help choosing the right contactor? Contact our experts at Proax for personalized guidance and recommendations.