Industrial contactors are the backbone of electrical control systems in manufacturing, commercial buildings, and industrial facilities. Whether you're controlling motors, lighting systems, or heavy machinery, choosing the right contactor can mean the difference between reliable operation and costly downtime.

This comprehensive guide covers everything you need to know about industrial contactors, from basic principles to advanced selection criteria, helping you make informed decisions for your electrical control applications.

What Are Industrial Contactors?

An industrial contactor is an electrically controlled switching device designed to make and break electrical circuits under load conditions. Unlike manual switches, contactors operate remotely through an electromagnetic coil, making them ideal for automated systems and applications requiring frequent switching.

Key Components of a Contactor

- Electromagnetic Coil: Provides the magnetic force to operate the contacts

- Main Contacts: Handle the primary electrical load (typically 3-pole or 4-pole)

- Auxiliary Contacts: Provide feedback signals and control interlocking

- Arc Extinguishing System: Safely manages electrical arcs during switching

- Mounting Base: Provides secure installation and connection points

Contactors vs. Relays: Understanding the Differences

Types of Industrial Contactors

At Proax, we provide a wide range of contactors to suit various industrial applications. Here’s an overview of our contactor offerings:

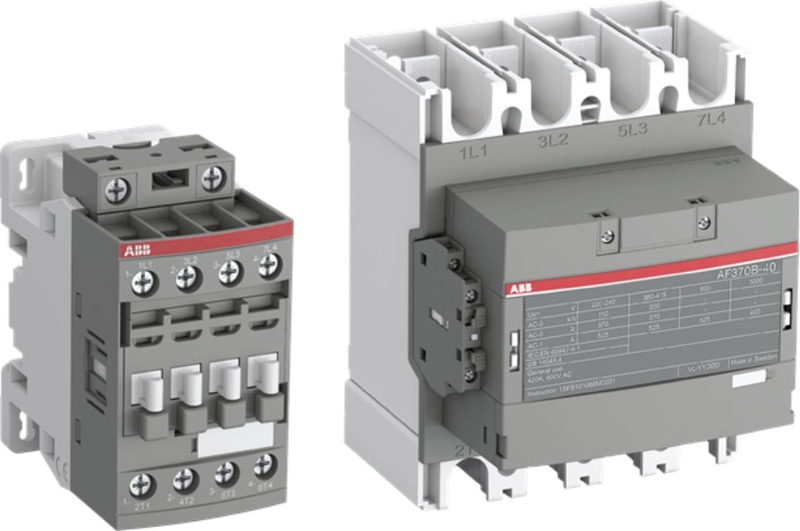

3-Pole Contactors

- Most common type for three-phase motor control

- Ratings from 9A to 800A

- Ideal for pumps, compressors, and conveyor systems

- Available in IEC and NEMA standards

4-Pole Contactors

Suitable for power switching applications. Offers reliable control for auxiliary circuits.

- Include neutral switching capability

- Essential for lighting control and single-phase loads

- Provide complete isolation of electrical circuits

- Required in many safety applications

Contactor Relays

Used for switching control and auxiliary circuits. Compact and efficient design for multiple applications.

Contactors for Capacitor Switching

Capacitor switching can generate extremely high current peaks during capacitor energization. UA..RA contactors are specifically designed with damping resistors to effectively manage these peaks without requiring additional limitations.

Contactors for DC Switching

GF, GAF, and GA contactors are engineered specifically for switching DC circuits up to 1500 V. These contactors are designed to efficiently break DC circuits, making them one of the most compact solutions on the market. Ideal for applications such as PV solar systems, EV charging stations, UPS, and energy storage systems.

Contactors for Safety Applications

AFS contactors are specifically designed to enhance safety in machine applications. Featuring factory-mounted contact blocks with mechanically linked and mirror contacts, these contactors ensure reliable monitoring and control of circuits. With ABB’s comprehensive safety component range, building protection systems becomes more straightforward and efficient.

Installation Contactors

ABB's installation contactors are designed for noise-sensitive environments, featuring a hum-free operation that sets them apart from conventional contactors. With a wide range of ratings from 16 A to 100 A, they are ideal for controlling lighting, heating, ventilation, motors, and pumps in residential and commercial buildings. The innovative AC/DC design eliminates hum, while tool-free accessories and manual or automatic versions provide added flexibility and convenience.

Definite Purpose Contactors

ABB's definite purpose contactors deliver reliable and efficient performance across a wide range of applications. These contactors are specifically designed for resistive heating, motor control, compressors in air conditioning and refrigeration systems, and food service equipment. Offering flexibility in size and configuration, they are built to meet the demands of various industrial environments.

ABB CR460 Lighting Contactors

The CR460 series lighting contactors are designed to offer maximum flexibility, ease of configuration, and reliable performance in lighting control applications. With a revolutionary modular design, these contactors meet diverse lighting control requirements while simplifying setup and maintenance. Ideal for commercial and industrial environments, they provide efficient lighting management with adaptable configurations.

ABB CR360L Lighting Contactors

The CR360L series lighting contactors are electrically held and designed to provide efficient lighting control in both industrial and commercial settings. Built on the reliable and proven NEMA starter platform, these contactors are available in a range of frame sizes to accommodate various load requirements. With current ratings from 30 to 300 amps, they are ideal for controlling lighting systems that include fluorescent, mercury arc, tungsten, and sodium lamp loads.

ABB CR160 Lighting Contactors

The CR160 series mechanically held lighting contactors are designed to efficiently control various lighting loads, including tungsten, fluorescent, mercury, and sodium. Suitable for non-inductive loads as well, these contactors feature silver cadmium oxide main contacts and silver tungsten arcing contacts for optimal performance.

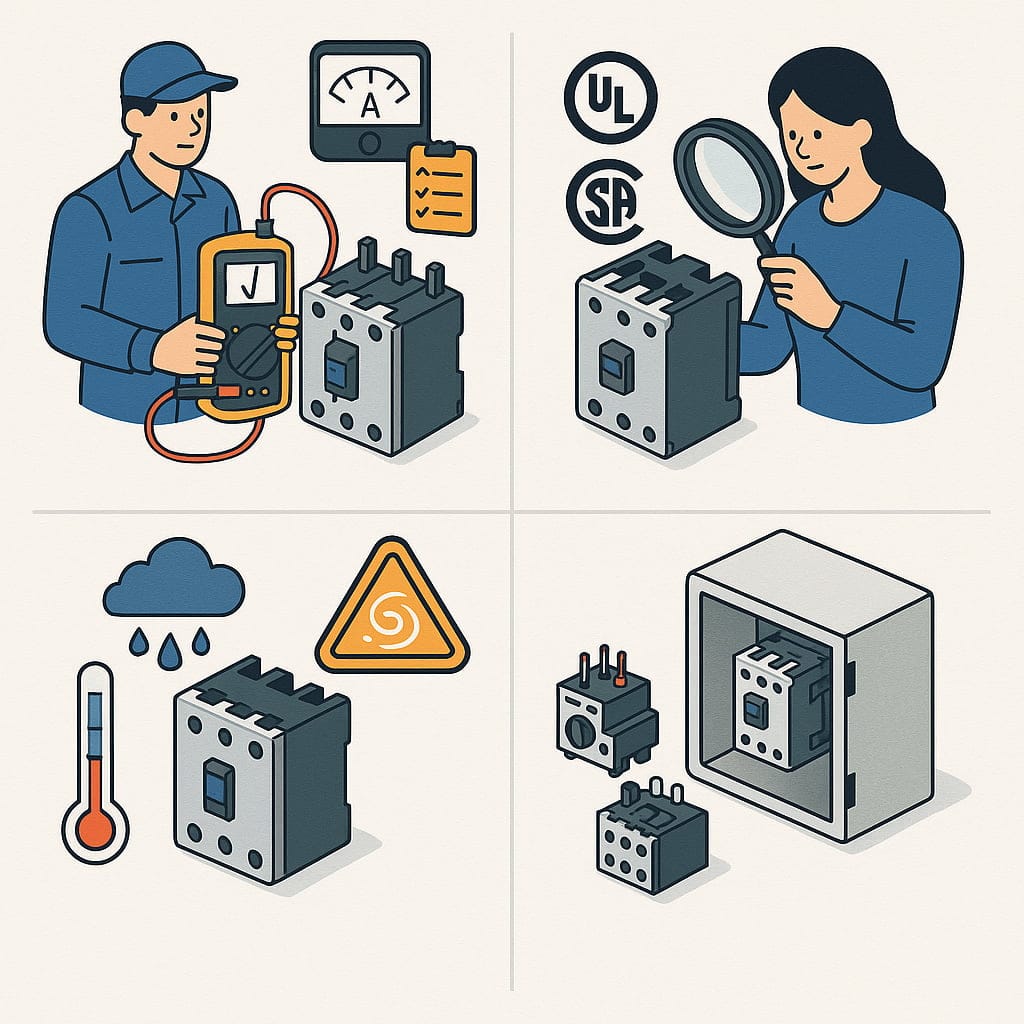

How to Choose the Right Contactor

Step 1: Determine Load Requirements

Consider voltage, current, and application type to select the appropriate contactor.

Step 2: Safety and Compliance

Ensure CSA and UL certifications to meet industrial safety standards.

Step 3: Consider Environmental Factors

Evaluate conditions like dust, moisture, and temperature.

Step 4: Select Features and Accessories

Choose overload relays, auxiliary contacts, and suitable enclosures to enhance safety.

Installation and Maintenance Tips

Installation Steps

- De-energize the circuit.

- Follow the wiring diagram carefully.

- Use appropriate tools for secure connections.

Maintenance Best Practices

- Periodically clean contacts to prevent corrosion.

- Inspect for overheating and replace worn components.

- Tighten loose connections regularly.

Troubleshooting Common Issues

- Buzzing Noise: Check coil voltage and secure connections.

- Frequent Tripping: Inspect for overload or short circuits.

- Contact Welding: Install surge protection to avoid this issue.

Conclusion

Selecting and maintaining the right industrial contactors is crucial for reliable electrical system operation. By understanding the different types, proper selection criteria, and maintenance requirements, you can ensure optimal performance and minimize downtime.

Whether you're designing new systems or upgrading existing installations, consulting with experienced electrical professionals ensures you get the most suitable solution for your specific application requirements.

Get Expert ABB Contactor Support

As Canada's trusted ABB authorized distributor, Proax combines extensive product knowledge with local engineering support. Our in-house engineers across 13 Canadian locations are ready to help you select, install, and maintain the right ABB contactor solution for your application.

Need technical assistance or want to place an order? Contact us today for expert consultation and competitive pricing on ABB contactors and accessories.