ABB contactors are among the most reliable electrical switching devices in industrial automation. As Canada's leading ABB authorized distributor, Proax has helped thousands of engineers and technicians select the right ABB contactor for their applications. Whether you're designing a new motor control panel or replacing existing equipment, choosing the right ABB contactor can significantly impact your system's performance and longevity.

This comprehensive guide covers everything you need to know about ABB contactors, from selection to troubleshooting, backed by our in-house engineering expertise across 13 locations in Canada.

What is an ABB Contactor?

An ABB contactor is an electrically controlled switch designed for making and breaking electrical circuits under normal operating conditions. Unlike generic contactors, ABB contactors feature advanced technologies like AF (Arc-Free) technology, electronic coil interfaces, and superior arc suppression systems that ensure reliable operation in demanding industrial environments.

ABB offers one of the industry's most comprehensive contactor portfolios, from compact 9A devices to heavy-duty 1650A units, serving applications across manufacturing, infrastructure, and renewable energy sectors throughout Canada.

Why Choose ABB Contactors?

- AF Technology: Industry-leading arc suppression for extended contact life

- Electronic Coil Interface: Wide voltage range operation (24-500V) with built-in surge protection

- Global Standards Compliance: CSA, UL, and IEC certifications

- 10 Million Operation Rating: Superior mechanical and electrical endurance

- Comprehensive Portfolio: From miniature to high-power applications

- Local Support: Proax engineers across Canada provide expert technical assistance

Key Types of ABB Contactors

ABB offers a wide range of contactors tailored to various needs. Here are the main types you need to know:

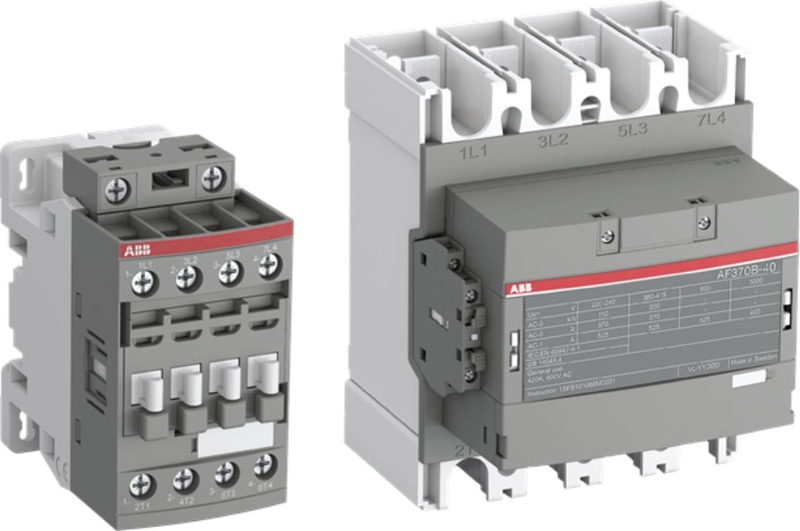

1. AF Series Contactors (Universal AC/DC Control)

- Ideal for: Motor control, power switching.

- Features:

- Universal coil voltage (100 V - 250 V AC/DC).

- Compact, reliable, and energy-efficient.

- Suitable for unstable networks, reducing downtime.

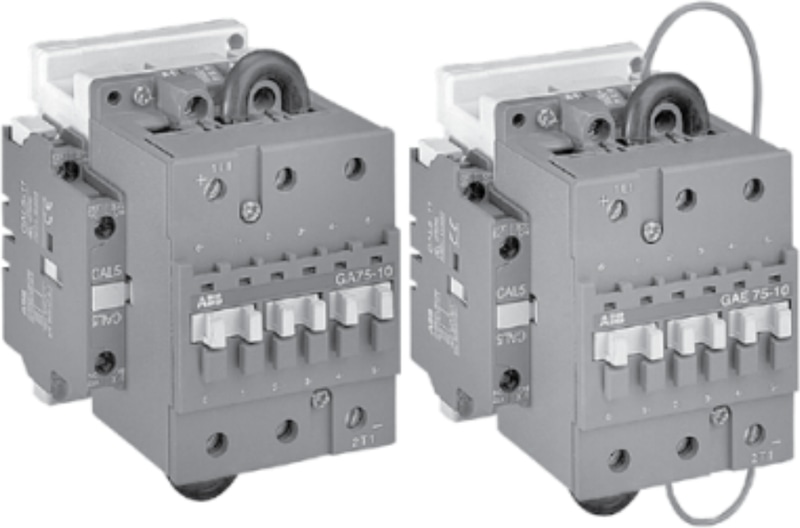

AF 3-pole Contactors

ABB's AF 3-pole contactors are the industry standard for three-phase motor control applications. These contactors feature revolutionary AF technology that allows use in all parts of the world and in all network conditions.

Key Features:

- Current ratings from 9A to 1650A

- Electronic coil interface (24-500V AC/DC)

- Built-in surge protection

- 10 million mechanical operations

- Global compatibility

Popular Applications:

- Three-phase motor starting

- Pump control systems

- Compressor applications

- Industrial machinery control

AF 4-pole Contactors

Application: Power switching applications

AF 4-pole contactors provide additional switching capacity for applications requiring neutral switching or enhanced control flexibility.

Applications:

- Neutral switching requirements

- Single-phase loads on three-phase systems

- Additional auxiliary functions

- Enhanced control flexibility

2. R Contactors (DC and AC Circuit Switching)

- Ideal for: High current and high voltage applications.

- Features:

- DC-1 rated current up to 5000 A.

- AC-1 rated operational current up to 5000 A.

- Suitable for slip ring motor control and DC circuit switching.

- Special Variants:

- AMA or AME for energy-saving and safety requirements.

- LOR and FOR for AC/DC coupling and slip ring motor control.

3. Specific Contactors

ABB capacitor switching contactors are specially designed to withstand unlimited peak current associated with capacitive loads.

Features:

- Heavy-duty contact materials

- Enhanced arc suppression

- Pre-insertion resistors available

- Synchronized switching capabilities

Applications:

- Power factor correction systems

- Capacitor bank switching

- Harmonic filter control

- Reactive power compensation

4.Contactors for DC Switching

Application: Battery systems and renewable energy

ABB DC switching contactors provide compact and efficient DC load control for modern energy applications.

Specialized Features:

- DC arc suppression technology

- Compact design for space-saving

- Voltage ratings up to 1000V DC

- Extended contact life

Applications:

- Solar power systems

- Battery storage systems

- EV charging infrastructure

- Industrial DC drives

AFS Contactors for Safety Applications

Application: Machine safety and emergency stop systems

AFS safety contactors help make your system safer with certified safety features for critical applications.

Safety Features:

- SIL 3 / PLe safety rating

- Fixed auxiliary contact blocks

- Mechanically linked mirror contacts

- Force-guided contacts

- CSA safety certification

Applications:

- Emergency stop circuits

- Safety interlock systems

- Machine guarding

- Process safety applications

Installation Contactors

Application: Building automation and HVAC

ABB installation contactors are designed for hum-free control in noise-sensitive environments.

Features:

- Silent operation technology

- Low power consumption

- Manual override functionality

- Compact modular design

- DIN rail mounting

Applications:

- HVAC control systems

- Building automation

- Lighting control

- Pump control

Definite Purpose Contactors

Application: HVAC and refrigeration systems

ABB definite purpose contactors combine flexibility with high performance for specific HVAC applications.

Features:

- CSA and UL certified

- NEMA standards compliance

- Optimized for HVAC loads

- Cost-effective solution

Applications:

- Air conditioning systems

- Heat pumps

- Refrigeration equipment

- Commercial HVAC

NEMA Lighting Contactors

ABB offers a complete range of mechanically and electrically held contactors for commercial and industrial lighting applications:

CR160 Lighting Contactors

- Heavy-duty lighting control

- Industrial environments

- High switching capacity

CR360L Lighting Contactors

- Reliable lighting control

- Commercial applications

- Energy-efficient operation

CR460 Lighting Contactors

- Advanced lighting control

- Complex lighting systems

- Time delay features

DC Circuit Switching Contactors

Application: Specialized DC applications

DC circuit switching contactors provide reliable switching for demanding DC applications with superior arc extinction capabilities.

How to Select the Right ABB Contactor

Step 1: Determine Application Requirements

For Motor Applications:

- Check motor nameplate for:

- Full Load Amperage (FLA)

- Horsepower (HP) or kilowatt (kW) rating

- Voltage rating (CSA standards)

- Starting method (DOL, star-delta, soft start)

- Consider duty cycle:

- AC-3: Normal motor starting and stopping

- AC-4: Frequent starting, plugging, and jogging

ABB Contactor Sizing Rule:

- Motor control: Select contactor HP rating ≥ motor HP rating

- Frequent operation: Choose AC-4 rated or upsize by one rating

Step 2: Voltage and Coil Selection

Main Circuit Voltage (Canadian Standards):

- 240V, 480V, 600V AC systems

- Match contactor voltage rating to system voltage

Control Coil Voltage:

- 24V DC: Most common for PLC control

- 120V AC: Traditional control circuits

- 240V AC: Direct motor voltage control

- Wide band coils: 100-250V AC/DC for versatile applications

Step 3: Environmental Considerations

Canadian Operating Conditions:

- Temperature range: Consider -40°C to +40°C for outdoor applications

- Humidity: High humidity environments require IP54+ protection

- Dust/moisture: Industrial environments may need IP65 rating

- Vibration: Mobile equipment requires enhanced mounting

ABB Contactor Pre-Installation Checklist

✓ Power isolation: Follow CSA lockout/tagout procedures

✓ Verify ratings: Match contactor specs to application

✓ Check torque specs: Use proper terminal torque values

✓ Plan wire routing: Separate power and control circuits per CEC

Installation Steps

- Mount the contactor

- Use DIN rail or screw mounting

- Ensure adequate clearance (minimum 10mm sides)

- Mount vertically for optimal performance

- Power circuit connections

- Connect L1, L2, L3 (line) terminals

- Connect T1, T2, T3 (load) terminals

- Use CSA-approved cable lugs

- Torque values: 1.2-2.5 Nm for standard terminals

- Control circuit wiring

- Connect coil terminals A1, A2

- Wire auxiliary contacts as required

- Use separate cable runs per CEC requirements

- Testing and commissioning

- Verify all connections

- Test coil operation at rated voltage

- Check contact operation with multimeter

- Perform insulation resistance test

Troubleshooting ABB Contactors

Common Problems and Solutions

1. Contactor Won't Energize

Possible Causes & Solutions:

- No control voltage: Check 24V supply to coil terminals A1, A2

- Faulty coil: Measure coil resistance (80-200Ω for 24V coils)

- Mechanical jam: Inspect for debris or damaged components

- Control circuit fault: Trace wiring from PLC output

2. Contactor Chattering/Buzzing

Possible Causes & Solutions:

- Low control voltage: Verify coil voltage (must be >85% rated)

- Poor connections: Check terminal torque

- Voltage fluctuations: Consider voltage stabilizer

- Dirty contacts: Clean electromagnet surfaces

3. Contacts Welding Together

Possible Causes & Solutions:

- Overload condition: Check motor current vs FLA

- Short circuit: Inspect load circuit

- Undersized contactor: Upgrade to higher rating

- High inrush current: Consider soft starter

4. Premature Contact Wear

Possible Causes & Solutions:

- Excessive duty cycle: Upgrade to AC-4 rated

- Poor arc suppression: Replace arc chute

- Wrong utilization category: Verify AC-3 vs AC-4

- Environmental contamination: Improve enclosure protection

Maintenance Schedule

Monthly Inspections

- Visual inspection for overheating

- Check for unusual operational noise

- Verify proper contact operation

- Clean external surfaces

Quarterly Maintenance

- Measure coil resistance

- Check contact resistance (<1mΩ)

- Inspect arc chute condition

- Verify mounting hardware

Annual Maintenance

- Complete cleaning and inspection

- Contact tip evaluation

- Insulation resistance testing

- Connection torque verification

Why Choose Proax for ABB Contactors

Local Expertise

- 13 locations across Canada for immediate support

- In-house engineers ready to assist with application selection

- Technical training and product support

- Same-day shipping from local inventory

Comprehensive Service

- Application engineering consultation

- Custom panel design services

- Emergency replacement support

- Preventive maintenance programs

Quality Assurance

- Genuine ABB products only

- Full manufacturer warranty

- Technical documentation included

- CSA compliance verification

Get Expert ABB Contactor Support

As Canada's trusted ABB authorized distributor, Proax combines extensive product knowledge with local engineering support. Our in-house engineers across 13 Canadian locations are ready to help you select, install, and maintain the right ABB contactor solution for your application.

Need technical assistance or want to place an order? Contact us today for expert consultation and competitive pricing on ABB contactors and accessories.