Official Distributor

Official DistributorSKU

MPN

PTWE 6-2/D19

Weight

0.549 kg

Series PTWE

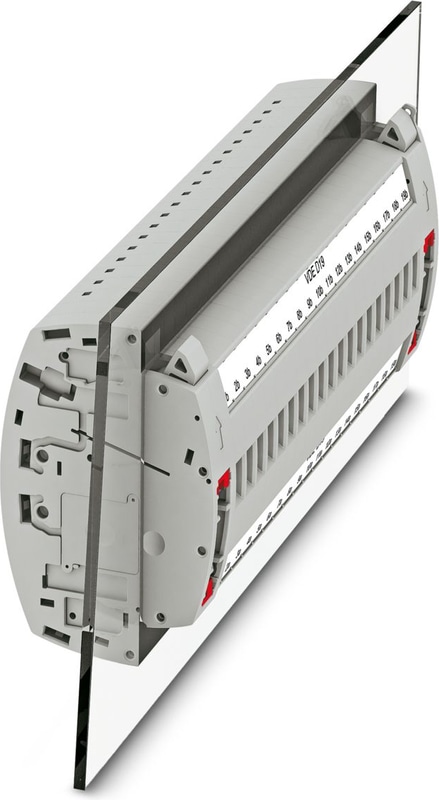

PTWE 6-2/D19 - Test terminal strip

Test terminal strip, VDE coded type D19, nom. voltage: 400 V, number of connections: 38, number of positions: 19, connection method: Push-in connection, 1 level, Rated cross section: 6 mm2, cross section: 0.5 mm2 - 10 mm2, mounting type: Wall mounting, color: gray

- Cost-effective, thanks to the tailored, modular design and use of standardized CLIPLINE complete accessories

- Space saving, thanks to compact, modular test terminal strips

- Maximum safety with leading and automatic transformer short circuit

- The integrated, robust switch contact is designed for the most stringent demands, and the use of high-quality materials ensures the transmission of signal currents, even after multiple actuations

Technical Specifications

Product properties

| Number of Positions | 19 |

| Pitch | 8.2 mm |

| Number of Connections | 38 |

| Number of rows | 1 |

| Potentials | 19 |

Insulation characteristics

| Overvoltage category | III |

Electrical properties

| Rated surge voltage | 4 kV |

| Maximum power dissipation for nominal condition | 1.31 W |

| Test surge voltage | 5 kV |

Connection data

| Number of connections per level | 38 |

| Nominal cross section | 6 mm² |

1 level

| Stripping length | 12 mm |

| Internal cylindrical gage | A5 |

| Connection in acc. with standard | IEC 60947-7-1 |

| Conductor cross section rigid | 0.5 mm² ... 10 mm² |

| Cross section AWG | 20 ... 8 (converted acc. to IEC) |

| Conductor cross section flexible | 0.5 mm² ... 6 mm² |

| Conductor cross section, flexible [AWG] | 20 ... 10 (converted acc. to IEC) |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 0.5 mm² ... 6 mm² |

| Flexible conductor cross section (ferrule with plastic sleeve) | 0.5 mm² ... 6 mm² |

| 2 conductors with the same cross section, flexible, with TWIN ferrule with plastic sleeve | 0.5 mm² ... 1.5 mm² |

| Maximum Load Current | 30 A (with 6 mm² conductor cross section) |

| Nominal Voltage | 400 V AC/DC |

| Nominal cross section | 6 mm² |

1 level Connection cross sections directly pluggable

| Conductor cross section rigid | 1 mm² ... 10 mm² |

| Conductor cross-section flexible (ferrule without plastic sleeve) | 1 mm² ... 6 mm² |

| Flexible conductor cross section (ferrule with plastic sleeve) | 1 mm² ... 6 mm² |

Dimensions

| Width | 188.6 mm |

| Height | 100 mm |

| Depth | 56.5 mm |

| Pitch | 8.2 mm |

| Plate thickness | 1 mm ... 4 mm |

Material specifications

| Color | gray |

| Flammability rating according to UL 94 | V0 |

| Insulating material group | I |

| Insulating material | PA |

| Static insulating material application in cold | -60 °C |

| Temperature index of insulation material (DIN EN 60216-1 (VDE 0304-21)) | 125 °C |

| Relative insulation material temperature index (Elec., UL 746 B) | 130 °C |

| Fire protection for rail vehicles (DIN EN 45545-2) R22 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R23 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R24 | HL 1 - HL 3 |

| Fire protection for rail vehicles (DIN EN 45545-2) R26 | HL 1 - HL 3 |

| Calorimetric heat release NFPA 130 (ASTM E 1354) | 27,5 MJ/kg |

| Surface flammability NFPA 130 (ASTM E 162) | passed |

| Specific optical density of smoke NFPA 130 (ASTM E 662) | passed |

| Smoke gas toxicity NFPA 130 (SMP 800C) | passed |

Surge voltage test

| Test voltage setpoint | 4.8 kV |

| Result | Test passed |

Temperature-rise test

| Requirement temperature-rise test | Increase in temperature ≤ 45 K |

| Result | Test passed |

| Short-time withstand current 4 mm² | 0.5 kA |

| Short-time withstand current 4 mm² | 0.3 kA |

| Short-time withstand current 4 mm² | 0.15 kA |

| Result | Test passed |

Power-frequency withstand voltage

| Test voltage setpoint | 1.89 kV |

| Result | Test passed |

General

| Terminal block mounting | 0.8 Nm ... 1 Nm |

Mechanical data

| Open side panel | No |

Mechanical strength

| Result | Test passed |

Attachment on the carrier

| Test force setpoint | 5 N |

| Result | Test passed |

| Note | Dimensions panel cutout see appendix. |

Test for conductor damage and slackening

| Rotation speed | 10 rpm |

| Revolutions | 135 |

| Conductor cross section/weight | 0.5 mm² / 0.3 kg |

| Conductor cross section/weight | 6 mm² / 1.4 kg |

| Conductor cross section/weight | 10 mm² / 2 kg |

| Result | Test passed |

Aging

| Temperature cycles | 192 |

| Result | Test passed |

Needle-flame test

| Time of exposure | 30 s |

| Result | Test passed |

Oscillation/broadband noise

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Spectrum | Service life test category 2, bogie-mounted |

| Frequency | f1 = 5 Hz to f2 = 250 Hz |

| ASD level | 6.12 (m/s²)²/Hz |

| Acceleration | 3.12g |

| Test duration per axis | 5 h |

| Test directions | X-, Y- and Z-axis |

| Result | Test passed |

Shocks

| Specification | DIN EN 50155 (VDE 0115-200):2008-03 |

| Pulse shape | Half-sine |

| Acceleration | 30g |

| Shock duration | 18 ms |

| Number of shocks per direction | 3 |

| Test directions | X-, Y- and Z-axis (pos. and neg.) |

| Result | Test passed |

Ambient conditions

| Ambient temperature (storage/transport) | -25 °C ... 60 °C (for a short time, not exceeding 24 h, -60 °C to +70 °C) |

| Ambient temperature (assembly) | -5 °C ... 70 °C |

| Ambient temperature (actuation) | -5 °C ... 70 °C |

| Permissible humidity (storage/transport) | 30 % ... 70 % |

Standards and Regulations

| Connection in acc. with standard | IEC 60947-7-1 |

Mounting

| Mounting Type | Wall mounting |

| Terminal block mounting | 0.8 Nm ... 1 Nm |

Accessories

Why Proax for Phoenix Contact 3069444?

Proax is an authorized distributor of Phoenix Contact 3069444 and one of Phoenix Contact's largest distributors in North America. Our highly skilled in-house technical team is ready to assist with any technical needs.

Have a question in mind? to help you get the right product as quickly as possible for your project. We're always here to help!

Short Lead Time

Highly Trained Staff

Live Chat

Technical Support

Local Inventory

60+ Years Experience

Additional Information

| Pack Size | 1 |

Recommended