Air regulators are essential components in pneumatic systems, designed to control and maintain the pressure of compressed air. By ensuring that the air pressure remains within a set range, they help protect equipment and optimize performance. Without an air regulator, fluctuations in pressure could lead to inefficiencies or even damage to the system.

The Importance of Air Regulators in FRL Units

In an FRL (Filter, Regulator, Lubricator) unit, the air regulator plays a key role in maintaining system efficiency. By regulating the pressure, it ensures that the air delivered to your equipment is at the optimal level, reducing the risk of wear and tear and extending the lifespan of the system. SMC’s air regulators are specifically designed to integrate seamlessly with FRL units, offering high performance and reliability.

Components of an FRL Unit

There are three primary components—Filter, Regulator, and Lubricator—each play a distinct role in ensuring clean, controlled, and lubricated air reaches your equipment. Let's look at those closer.

Filters

The filter in an FRL unit is designed to remove contaminants such as dust, oil, and moisture from the compressed air. Clean air is essential for maintaining the performance and longevity of pneumatic tools. By filtering out these contaminants, the filter prevents damage and ensures that the air regulator and lubricator can perform their functions effectively.

Regulators

Pressure regulators unit that controls the air pressure delivered to the system. By adjusting the regulator, you can set the desired pressure level, which is then maintained consistently during operation. This ensures that all connected pneumatic tools receive the correct pressure, improving efficiency and reducing wear and tear.

Lubricators

The lubricator adds a fine mist of oil into the airflow to reduce friction within moving parts of pneumatic tools and machinery. This lubrication minimizes wear on seals and other components, enhancing overall durability and efficiency. Proper lubrication is essential for smooth operation and reduced maintenance needs.

Integrated Units

Many modern FRL units integrate these three components into a single assembly for convenience and space-saving purposes. These integrated combination units simplify installation and maintenance while providing comprehensive treatment for compressed air systems.

Incorporating quality FRL components into your pneumatic setup ensures reliable performance, prolongs equipment life, and reduces downtime due to contamination or inadequate pressure control issues.

Smc’s Range of Air Regulators and FRL Units

SMC offers a comprehensive range of air regulators, modular and non-modular FRL units designed to meet the diverse needs of various industries and applications. Known for their precision, durability, and innovation, SMC regulators provide reliable pressure control across a wide range of conditions.

Key Features of SMC’s Modular F.R.L. Units:

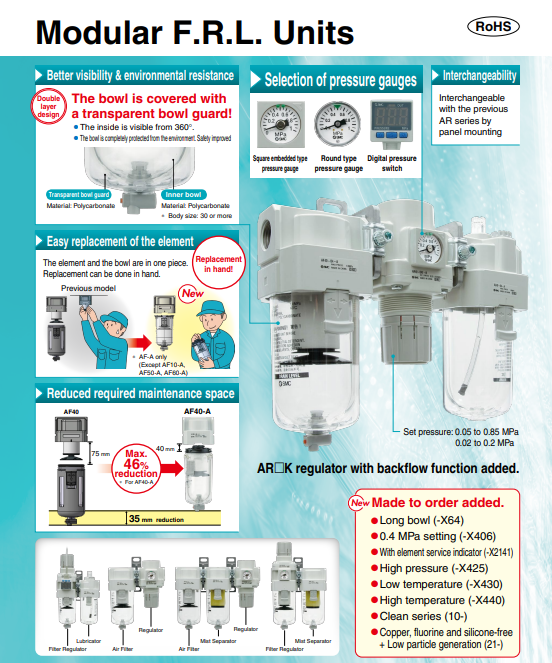

- Transparent Bowl Guard: SMC’s regulators feature a transparent bowl guard that allows for 360° visibility, making it easy to monitor the condition of the element. This bowl is constructed from polycarbonate for better visibility and environmental resistance, with an inner bowl for added safety.

- Selection of Pressure Gauges: SMC offers a variety of pressure gauges, including square embedded type, round type, and digital pressure switches. This flexibility allows you to choose the gauge that best suits your application’s needs.

- Easy Replacement of the Element: SMC has designed their FRL units with user-friendly maintenance in mind. The element and bowl are combined into a single piece, allowing for quick and easy replacement. This design reduces downtime and makes maintenance more efficient.

- Reduced Maintenance Space: SMC’s new AF40-A models have been redesigned to require less maintenance space, reducing the unit height by up to 46%. This compact design is ideal for applications where space is at a premium.

- Customization Options: SMC offers made-to-order options for their FRL units, including long bowls, low temperature options, high-pressure settings, and clean series options that use copper, fluorine, and silicone-free materials. These customizable features ensure that SMC’s products can meet specific industry requirements.

- Backflow Function: The ARK regulator comes with an added backflow function, providing enhanced performance and versatility in various pneumatic applications.

Applications of Air Regulators in Various Industries

Manufacturing: Precision in Automation and Tool Performance

In the manufacturing industry, maintaining consistent pressure is essential for the smooth operation of automated systems and tools. SMC air regulators are known for their precision and reliability, which are critical in ensuring that pneumatic equipment operates efficiently. Whether it's controlling the pressure for robotic arms or ensuring the steady flow of air to production tools, SMC regulators help maintain the high standards required in modern manufacturing. With Proax’s support across 13 locations in Canada, manufacturers have access to both standard and custom-built pneumatic solutions to meet their specific needs.

Healthcare: Reliability in Medical Devices

In the healthcare sector, the precision and reliability of air regulators are crucial, especially in applications involving life-supporting devices or sensitive diagnostic equipment. SMC regulators are trusted in the healthcare industry for their ability to maintain exact pressure levels, which is vital for the safe and effective operation of medical devices. From ventilators to pneumatic surgical tools, SMC’s air regulators ensure that healthcare professionals can rely on their equipment to perform flawlessly. Proax enhances this by providing tailored solutions and expert support, ensuring that healthcare providers have the right equipment for their critical applications.

Automotive: Efficiency in Pneumatic Systems

The automotive industry relies heavily on pneumatic tools and systems for tasks ranging from assembly to painting. SMC air regulators are widely used to control the pressure in these systems, ensuring consistent performance and quality. Whether it's in the production line or in the maintenance of vehicles, SMC regulators contribute to the efficiency and reliability of operations. Proax’s extensive network and custom build capabilities mean that automotive manufacturers and service providers can access the precise pneumatic components they need, built to their specific requirements.

Other Industries: Versatility Across Applications

Beyond manufacturing, healthcare, and automotive, SMC air regulators are essential in a wide range of other industries. From food and beverage processing, where hygiene and precision are paramount, to aerospace, where reliability and performance are critical, SMC regulators provide the necessary pressure control for various applications. Proax supports these industries by offering a wide selection of SMC products and the ability to customize pneumatic solutions to meet the unique challenges of each field.

As an authorized elite SMC distributor, Proax not only provides access to the full range of SMC products but also offers expert support to help you select the best regulator for your needs. With 13 locations across Canada, we are fully equipped to meet your FRL requirements.

In addition to stocking a comprehensive range of FRL units, we have custom build shops where we can design and assemble pneumatic components tailored to your specific applications. Contact us today for your custom FRL needs and experience the reliability and performance that SMC and Proax bring to your pneumatic systems.