Selecting the right fuse for your electrical system isn't just about matching numbers—it's a critical design decision that directly impacts safety, reliability, and performance. At Proax, we understand that proper fuse selection can mean the difference between smooth operations and costly downtime or even dangerous failures.

Why Proper Fuse Selection Is Critical

A fuse serves as the intentional "weakest link" in your electrical circuit, designed to sacrifice itself when dangerous current levels threaten your equipment and personnel. But choosing the wrong fuse can lead to:

- Nuisance trips that interrupt operations unnecessarily

- Equipment damage from inadequate protection

- Safety hazards from improper interruption capabilities

- Compliance issues with industry standards and regulations

Let's explore the essential factors to consider when selecting the right fuse for your specific application needs.

Key Selection Criteria for Fuses

1. Current Rating: Finding the Sweet Spot

The current rating of your fuse should be carefully calculated to match your application's normal operating conditions while providing protection against overloads.

Best Practice: Select a fuse with a current rating approximately 125% of your circuit's maximum normal operating current. For example, if your circuit typically draws 8A, a 10A fuse provides an appropriate safety margin.

Application Consideration: Different loads have different current profiles:

- Motor circuits experience high inrush currents during startup

- Transformer circuits can experience magnetizing inrush when energized

- Electronic circuits may need tighter protection margins

2. Voltage Rating: Never Compromise

A fuse's voltage rating must always meet or exceed the maximum voltage in your circuit—no exceptions.

Safety Rule: Choose a fuse with a voltage rating at least 20% higher than your system's maximum operating voltage to account for transients and fluctuations.

Important Distinction: AC and DC applications require different considerations:

-AC fuses benefit from natural current zero-crossing for arc extinction

-DC fuses must be specifically rated for DC use, as interrupting DC is more challenging

3. Breaking Capacity: Prepared for the Worst

The fuse's interrupting capacity (also called breaking capacity) must exceed the maximum fault current available in your system.

Critical Safety Factor: Underestimating available fault current is dangerous—a fuse that cannot safely interrupt a fault may rupture violently or allow continued current flow.

Calculation Tip: Work with your electrical engineer to determine the maximum available fault current at the installation point, then select a fuse with an interrupting rating that exceeds this value with margin.

4. Time-Current Characteristics: Speed Matters

Different applications require different fuse response speeds:

| Response Type | Characteristics | Typical Applications |

|---|---|---|

| Fast-Acting | Quickly responds to overloads | Electronic protection, semiconductor safeguarding |

| Time-Delay | Tolerates temporary overloads | Motors, transformers, and loads with inrush currents |

| Very Fast-Acting | Extremely rapid response | Sensitive semiconductor protection |

Application Matching: Select time-current characteristics based on normal operating conditions. For example, motors that draw 6-8 times their rated current during startup require time-delay fuses to prevent nuisance tripping.

5. Environmental Factors: The Often Overlooked Consideration

Ambient conditions significantly impact fuse performance:

Temperature Effects: Fuses are typically rated at 25°C (77°F). Higher ambient temperatures require derating:

- At 60°C (140°F), you may need to increase fuse size by 15-25%

- At lower temperatures, fuse clearing time may increase

Installation Environment: Consider exposure to:

- Vibration and mechanical stress

- Humidity and corrosive atmospheres

- Altitude (affects air's dielectric strength)

Mersen Fuse Series: Finding Your Perfect Match

As an authorized Mersen distributor, Proax offers access to Mersen's comprehensive range of high-quality fuses. Here's how to match Mersen series to your specific application needs:

Class J Fuses: Versatile Protection for Industrial Applications

- Best For: General power distribution, feeders, and loads requiring quick response

- Key Features: Excellent current-limiting protection, 600VAC/300VDC rating

- Interrupting Rating: Up to 200kA

- Application: Ideal for general circuits without significant inrush current

- Best For: Motor circuits, transformers, and branch circuits

- Key Features: Superior current-limiting with time-delay, SmartSpot indicator

- Voltage Rating: 600VAC/400VDC

- Application: Perfect for applications with high inrush currents that need time-delay protection

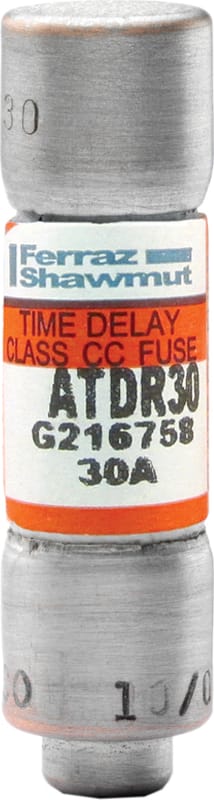

Class CC Fuses: Compact Protection for Small Circuits

- Best For: Small motors, branch circuits, and control systems

- Key Features: Best time-delay characteristics in its class, excellent cycling capacity

- Electrical Ratings: 600VAC/300VDC, 200kA interrupting capacity

- Application: Ideal for small motor protection and sensitive branch circuits

Miniature Fuses: Protection for Electronic Applications

- Best For: Electronic circuits requiring time-delay

- Form Factor: Glass, miniature (1/4" × 1-1/4")

- Voltage Rating: Up to 250VAC

- Application: Electronic equipment with temporary overloads

- Best For: Sensitive electronic protection

- Form Factor: Glass, miniature (1/4" × 1-1/4")

- Current Range: 1/10A–30A

- Application: Electronic circuits requiring quick response

- Best For: High-current electronics

- Form Factor: Ceramic, miniature (1/4" × 1-1/4")

- Application: Equipment like microwave ovens that need time-delay protection

- Best For: Electronic circuit protection requiring speed

- Application: Fast protection for sensitive electronic equipment

Selection Methodology: A Step-by-Step Approach

Follow these steps to select the optimal fuse for your application:

- Define Your Circuit Parameters:

- Normal operating current

- Maximum system voltage

- Available fault current

- Load characteristics (resistive, inductive, motor, etc.)

- Identify Special Considerations:

- Inrush current requirements

- Ambient temperature conditions

- Space constraints

- Required agency approvals

- Select Fuse Class and Series:

- Match application needs to appropriate fuse class

- Choose time-current characteristics (fast-acting vs. time-delay)

- Verify Ratings Meet or Exceed Requirements:

- Current rating (with appropriate margin)

- Voltage rating (equal to or greater than system voltage)

- Interrupting capacity (greater than available fault current)

- Confirm Physical Installation Requirements:

- Mounting method compatibility

- Space availability

- Accessibility for maintenance

Fuse Selection Checklist

| Selection Criteria | What to Verify | Common Pitfalls to Avoid |

|---|---|---|

| Current Rating | Exceeds normal load by appropriate margin | Oversizing reduces protection; undersizing causes nuisance trips |

| Voltage Rating | ≥ Maximum circuit voltage (with safety margin) | Using AC-rated fuses in DC applications |

| Interrupting Capacity | > Maximum available fault current | Underestimating available fault current |

| Application Type | Matches load characteristics (motor, electronic, etc.) | Using fast-acting fuses with inrush loads |

| Ambient Temperature | Consider derating for temperatures above 25°C | Failing to adjust for high-temperature environments |

| Agency Approvals | Meets UL, CSA, IEC requirements as needed | Missing required certifications for your application |

Future-Proofing Your Protection Strategy

When designing electrical systems, consider these forward-looking approaches:

- Anticipate Growth: Select fuses with some headroom if system expansion is likely

- Standardize Where Possible: Reduce inventory and maintenance complexity

- Consider Coordination: Ensure proper selectivity between upstream and downstream protection devices

- Document Your Selections: Maintain records of fuse selections and the reasoning behind them

Expert Support When You Need It

At Proax, we understand that fuse selection can be complex. Our in-house technical specialists can help you navigate the selection process and ensure optimal protection for your specific application.

Explore our complete range of industrial fuses and benefit from our status as an authorized distributor for Mersen, a global leader in electrical power and advanced materials.

Whether you're designing a new system or upgrading existing protection, our team is ready to help you select the right fuse for your application—because when it comes to electrical protection, there's no room for compromise.

Contact us today to discuss your specific protection needs and discover why Proax is the trusted partner for electrical protection solutions.