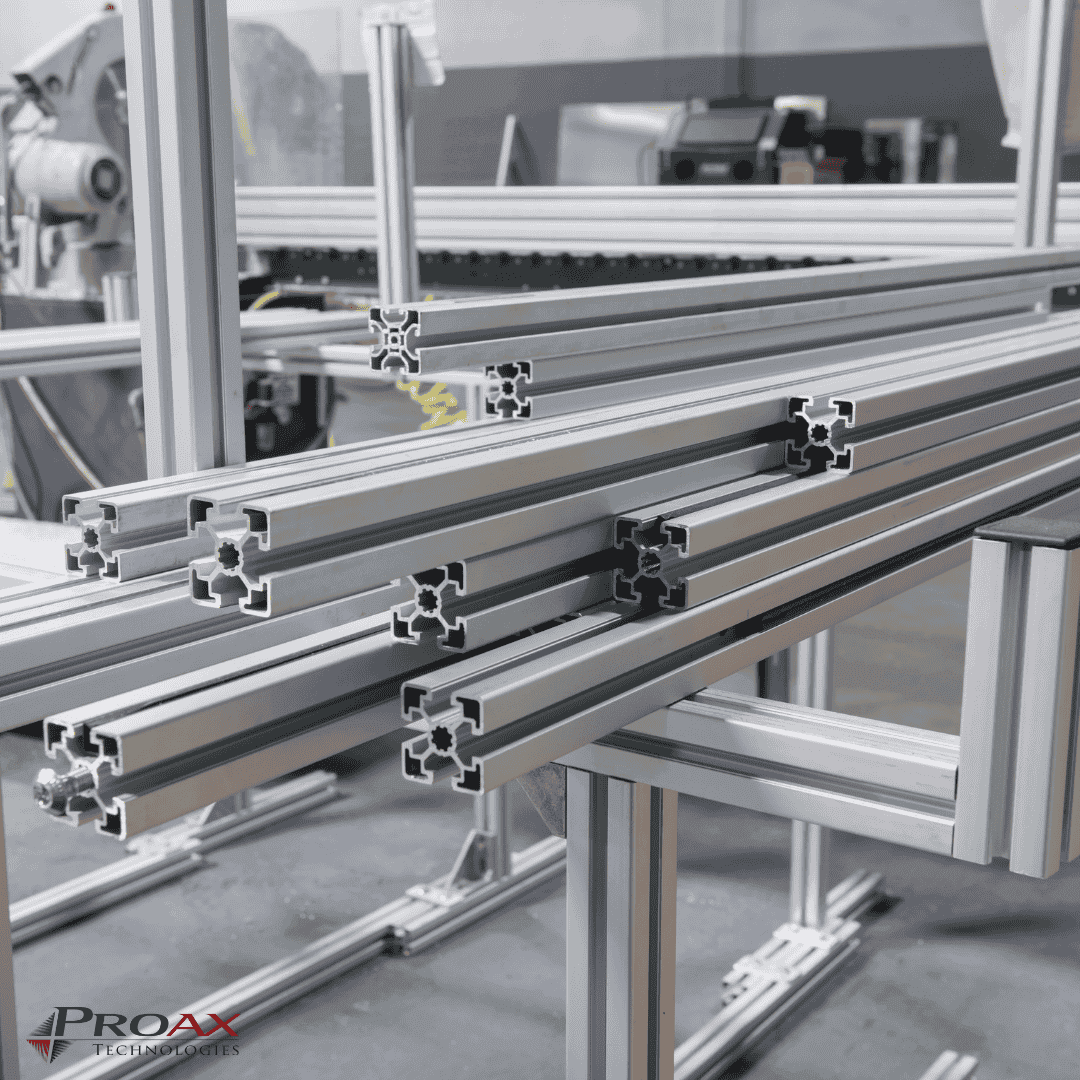

Aluminum Extrusions

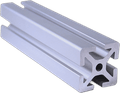

Aluminum extrusions are shapes formed by pushing aluminum through a die, creating solid, semi-hollow, or hollow profiles. Known for their strength, stability, corrosion resistance, and light weight, they are ideal for various applications. Discover our range of profiles like 1010, 1515, and 4040, with lengths from 2 meters to 240 inches. Customize with fasteners, T-nuts, and connectors in finishes like black, clear, and zinc-plated steel. Find the perfect aluminum extrusion to meet your needs.

B-SERIES Extrusion

Hardware

Metric Extrusions

Aluminum Extrusion Accessories

Brackets & Connectors

Fasteners

Panels

Fraction Extrusions

Tailored to Your Needs

Custom Cut Aluminum Extrusions

At Proax, we understand that one size doesn’t fit all. That’s why we offer custom cutting services for our TSLOTS aluminum extrusions.

How It Works:

Browse and Select:

Choose the TSLOTS aluminum extrusion profile that suits your project.Place Your Order:

Add the product to your cart and proceed to checkout.Specify Your Cut:

In the order notes, simply mention the exact length and quantity you need.We Do the Rest:

Our team will precisely cut your extrusions before shipping.

Related Categories

Fractional Aluminum Extrusions

Key Features:

- Versatility: Suitable for custom framing, machine guarding, and workstations.

- Easy Assembly: Compatible with various connectors and fasteners for quick setup.

- Strength: Robust construction ensures durability and reliability in demanding environments.

- Corrosion Resistance: Aluminum material provides excellent resistance to corrosion.

Metric Aluminum Extrusions

Key Features:

- Precision: Designed to meet metric standards, offering high precision for complex assemblies.

- Compatibility: Works seamlessly with other metric components and systems.

- Flexibility: Available in various profiles and sizes to suit different project requirements.

- Enhanced Strength: Engineered for superior load-bearing capacity.

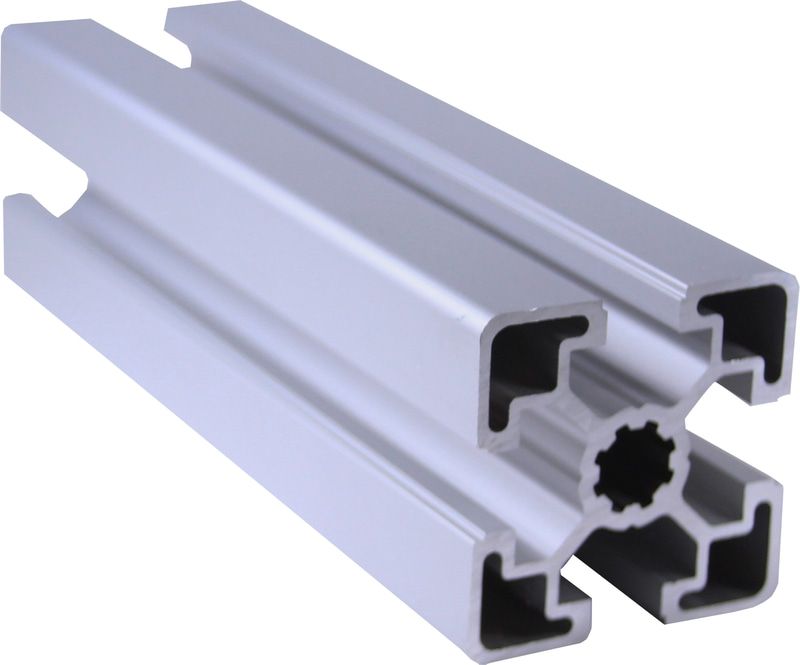

B-Series Aluminum Extrusions

Key Features:

- High Load Capacity: Suitable for heavy-duty applications, providing strong support and stability.

- Customizability: Can be easily customized with additional accessories and modifications.

- Durability: Made from high-quality aluminum, ensuring long-term performance.

- Easy Integration: Designed for easy integration into existing systems and frameworks.

Aluminum Extrusions FAQs

Aluminum extrusion is a process where aluminum alloy is heated and forced through a die, creating a specific cross-sectional profile. This method allows for the production of solid, semi-hollow, and hollow shapes, which are known for their strength, stability, and corrosion resistance.

Aluminum extrusions provide several advantages, including high strength-to-weight ratio, excellent corrosion resistance, and ease of machining. They are also versatile and can be customized to meet specific design requirements, making them ideal for structural and architectural applications.

In industrial settings, aluminum extrusions are used in frameworks, machine guards, workstations, and conveyor systems. Their lightweight and durable properties make them perfect for constructing robust and adaptable structures that enhance productivity and safety.

Selecting the right aluminum extrusion involves considering factors such as the required strength, load-bearing capacity, and environmental conditions. It's important to choose the correct profile shape, alloy type, and finish based on your specific application needs. Consulting with our team of experts can help you make an informed decision to ensure optimal performance and durability.