Distributeur Officiel

Distributeur OfficielBy Omron

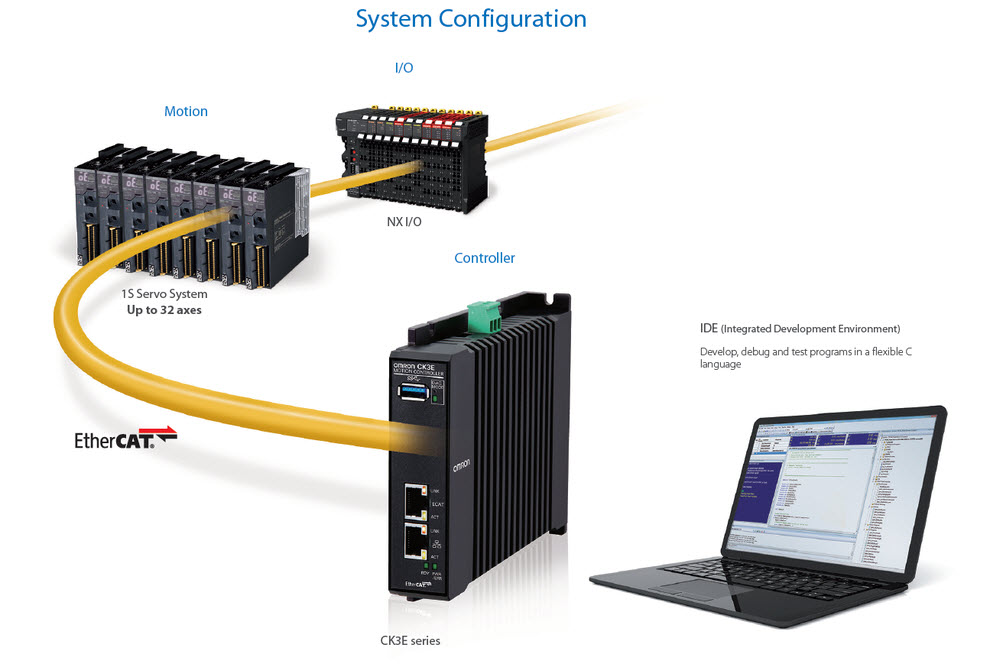

CK3E Programmable Multi Axis Controller

- 32, 16 or 8 axes motion control

- Up to 250 μs cycle time

- Compatible with standard G-Code functions

- Save space & wiring thanks to compact design

- CAD/CAM for easy motion control

- EtherCAT for flexible configuration

Compact design

Built-in ports:

- Modbus TCP for PLC communication, visualization and programming

- EtherCAT for real-time machine control

- USB port for data logging or G-Code download

Complex kinematics

Complex mechanics can be controlled thanks to the matrix handling and the space conversion. Special applications like Hexapod telescope mirror positioning, can be easyly operated by the kinematics handling functionality.

Leveraging features for accurate machining application

G-Code

Standard RS-274 G-Code interpreter. User-writable subroutines for customized implementation of G, M, T and D-codes. Flexibility to adapt the syntax and to work in combination with any CAD/CAM software.

Cutter compensation 2D/3D

Tool diameter and shape compensation, matching the cutting point exactly as specified in G-Code.

Fast processor + large program buffer

Fast processor can handle over 10, 000 blocks per second and up to 1Gb part programs.

Block Retrace for reversing the path

Path can be reverted in order to remove the tool from cutting area.

Advanced Block Lookahead

Instructions in the buffer are analyzed in advance, movements are blended and optimized in speed and acceleration for a better performance.

Tangent tool management

Tools with a cutting direction require a tangent path positioning.Documents

CK3E Programmable Multi-Axis Motion Controller

Advanced motion control system in a compact size, capable of controlling up to 32 axes of motion and incorporating customized control algorithms.

- 32, 16 or 8 axes motion control

- Up to 250 μs cycle time

- Compatible with standard G-Code functions

- Save space & wiring thanks to compact design

- CAD/CAM for easy motion control

- EtherCAT for flexible configuration

Compact design

Built-in ports:

- Modbus TCP for PLC communication, visualization and programming

- EtherCAT for real-time machine control

- USB port for data logging or G-Code download

Complex kinematics

Complex mechanics can be controlled thanks to the matrix handling and the space conversion. Special applications like Hexapod telescope mirror positioning, can be easyly operated by the kinematics handling functionality.

Leveraging features for accurate machining application

G-Code

![]()

Standard RS-274 G-Code interpreter. User-writable subroutines for customized implementation of G, M, T and D-codes. Flexibility to adapt the syntax and to work in combination with any CAD/CAM software.

Cutter compensation 2D/3D

![]()

Tool diameter and shape compensation, matching the cutting point exactly as specified in G-Code.

Fast processor + large program buffer

![]()

Fast processor can handle over 10,000 blocks per second and up to 1Gb part programs.

Block Retrace for reversing the path

![]()

Path can be reverted in order to remove the tool from cutting area.

Advanced Block Lookahead

![]()

Instructions in the buffer are analyzed in advance, movements are blended and optimized in speed and acceleration for a better performance.

Tangent tool management

![]()

Tools with a cutting direction require a tangent path positioning.

| Type | Contrôleur multiaxe |

| Nombre d'axes | 4 |

| Durée du cycle [Max] | 250 µs |

| Capacité du programme | 1 GB |

| Mouvement et réseau d'entrées/sorties (E/S) en temps réel | EtherCAT |

| Langage de programmation | G-Code/ANSI C/Langage de programmation original |

| Connexion de programmation | Ethernet |

| Largeur | 130 mm |

Pourquoi Proax pour Omron CK3E-1210?

Proax est le distributeur autorisé de Omron CK3E-1210. Nous sommes le plus grand distributeur d'Omron au Canada. Notre équipe technique interne, qui est hautement qualifiée, est prête à répondre à vos besoins techniques!

Avez-vous une question? pour vous aider à obtenir le bon produit le plus rapidement possible pour votre projet. Nous sommes toujours là pour vous aider!

| Autres noms | CK3E1210 |

| Taille de l'emballage | 1 |