LD Series Autonomous Mobile Robots

Self-navigating autonomous Mobile Robot (AMR).

The World’s Most Popular Mobile Robot Solution

Integrated

Compatible with other OMRON robots, mobile robot fleets and MES systems.

Intelligent

Optimizes routing and adapts to changing conditions on the fly.

Interactive

Works safely with people and has an intuitive setup.

Fully autonomous intelligent vehicles

Our mobile robots are fully autonomous intelligent vehicles that increase throughput, reduce machine dwell time, eliminate errors, improve material traceability, and allow employees to focus on tasks that require complex human skills. What’s more, unlike traditional AGVs, our mobile robots navigate by the natural features of the facility and require no expensive facility modification.

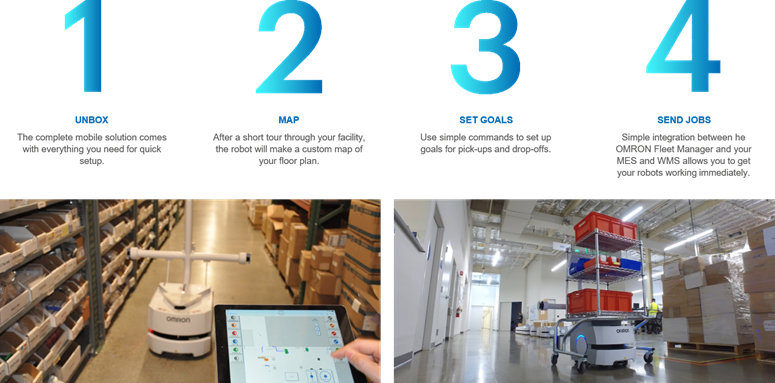

Easy Installation

OMRON mobile robots are easy to get up and running, requiring no construction such as the installation of magnets, and minimal programming. In addition, our software integrates with your other systems so you can get the solution up and running in minimal time.

- No construction required

- Easy integration with MES, ERP, and WMS

- Enhanced security to comply with IT systems

- Autonomous navigation doesn’t require preset routes, magnets, or beacons

- Automatic software updates across fleet while maintaining continuous work flow

Flexible Functionality

OMRON’s mobile solutions are extremely versatile and can be adapted to perform a wide variety of tasks and applications. With payloads ranging from 60kg to 250kg available in multiple form factors and protection ratings, LD series mobile robots are perfectly suited for most small to midrange material transport applications. We’re also scalable, so we can grow with your business.

Featured Packed by Design

Designed to meet the industry’s latest requirements, our mobile robots interact with people to promote a collaborative, safe working environment. Safety lasers and rear facing sensors allow our robots to detect obstacles in their path to prevent collisions.

Key Features:

- Onboard laser sensing and navigation

- Rearward obstacle detection

- Automatic dock charging

- Power and control of custom topper units

Safety Features:

- Avoids static and moving obstacles

- Additional E-stops easily added

- Complies with ISO EN1525, JIS D6802 and ANSI B56.5 safety standards

LD-60/90 Features

LD-250 Features

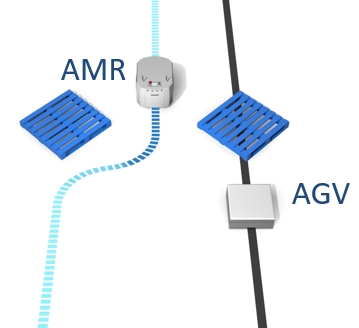

AMR vs. AGV - The Difference is Flexibility

AGVs require a predefined path to follow, either a network of magnetic lines on the floor or beacons on the walls. So although AGVs allow modifications to production lines, facilities will need to install new equipment every time the AGV path is changed, leading to downtime and extra costs.

Unlike AGVs, which will stop at obstacles indefinitely, AMRs avoid stationary or moving obstacles and automatically reroute themselves when necessary. AMR paths automatically change without human intervention, making operations more flexible and decreasing total cost of ownership.

AMRs can safely navigate without the use of floor magnets or wall-mounted beacons. An AMR will first create a baseline map of a facility using built-in sensors, then will constantly detect its surroundings. When processes change, AMRs can easily change as well, creating networks of new routes or being reassigned to new tasks.

Sensors:

- Safety Rated Main Laser

- Lower Laser

- Side Lasers (Patented)

- Front Bumper

- Rear Sonar

- Rear Laser

1 Safety std: ISO 12100, ISO 14121-2, ISO 13849-1, IEC61010(battery only), IEC 60950(battery only), EN 1525, ANSI B56.5 Part 3, JIS D6802, IEC 60204

Mapping and Navigation

Robust Navigation with LD Acuity Localization.

Acuity provides an additional method of "localization" to the onboard laser, to allow the robot to operate in frequently changing environments. It identifies overhead lights and overlays the "light map" with the "floor map" It also allows the robots to move easily across wide-open areas in large warehouses.

Our LD Electro-Static Discharge (ESD) Skin is a protective measure to protect both the robot and ESDS (ESD Sensitive) items within the environment to which the robot operates from damage due to the buildup and discharge of static electrical energy created by field strengths.

- Protection for field strengths above approximately 40 kV/cm of air

- Skins designed to resist the static build up

- 100% compatible with existing standard LD robots, optional skin sets are also available

- Protection for both the robot and Electrostatic Sensitive Discharge Sensitive (ESDS) items

0 Articles

Nom | Stock |

|---|---|